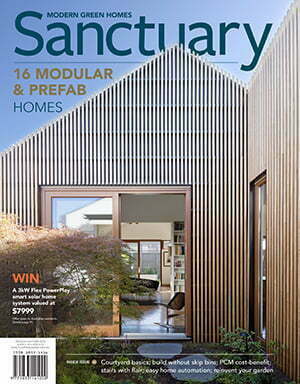

Sanctuary 42 out now – Prefab performers

Sanctuary 42 is out now, with a special feature on the latest developments in the modular & prefab industry in Australia.

If you still think prefab is code for ‘cookie cutter’ you’d be wrong. Led by countries such as Sweden where over 80 per cent of houses are now built in factories, there has been a widespread architectural revolution when it comes to prefabricated construction. Now, almost any design is possible.

In our Modular & Prefab special feature in Sanctuary 42, we speak with 16 companies offering what can be called ‘prefabricated’, ‘factory’ or ‘off-site’ construction services – read our summary here. We have selected those with a focus on the residential sector and which provide options for high building energy star ratings, renewable materials and cost-effective production. Their approaches fall into two main construction categories – modular and panelised – but within these is a huge range of different products on offer.

In our Modular & Prefab special feature in Sanctuary 42, we speak with 16 companies offering what can be called ‘prefabricated’, ‘factory’ or ‘off-site’ construction services – read our summary here. We have selected those with a focus on the residential sector and which provide options for high building energy star ratings, renewable materials and cost-effective production. Their approaches fall into two main construction categories – modular and panelised – but within these is a huge range of different products on offer.

Since Sanctuary last looked at this sector in issue 31, modular construction remains the predominant approach. The change has been in the number of companies offering panelised systems which, on our count, has doubled in three years. Considered the ‘European’ approach, many are airtight, interlocking systems that can achieve passivhaus standard. The panels range from structural insulated panels (SIPs) using high-density foam insulation, to timber wall panels filled with glasswool and many other combinations.

Efficiencies of prefab/off-site construction can be brought to any design, though it helps if the design is done with the capabilities of the construction method in mind. ‘De-risking’ the building process by disclosing costs and timeframes to clients up front is also a feature of this industry.

Some prefab companies now offer partnerships with recommended architects and local trades, but a surprising number are architecturally driven and have full design/build teams in-house. Melbourne appears to be the hotbed of action when it comes to innovating with prefabrication, but the rest of Australia (and New Zealand) has growing businesses too – although with this building method geared for transportation, location is little barrier.