Small-scale plastic recycling

Plastic pollution threatens the unique coral reefs of Timor Leste. Renew’s Harry Andrews reports on a local project that is collecting and recycling that waste with significant economic and environmental benefits.

The world’s oceans are infested with plastics. It is estimated there are 5.25 trillion pieces of plastic in the oceans with 269,000 tonnes afloat. Regardless of the origin of the plastic, once in the ocean it becomes a global problem as it travels far and wide on the ocean currents. And it’s an enduring problem as a plastic bag takes 20 years to disintegrate, while a bottle cap takes 450 years. The most significant impact of marine plastics is the harm to countless sea creatures and birds as they mistake the plastic for food.

On Atauro Island, 30 km offshore from Timor Leste’s capital, Dili, the impact of marine plastic is obvious as soon as you step off the ferry. The nearby beach is strewn with plastic that has been washed ashore.

Yet this is an important marine area, sitting within the world-renowned coral triangle. This triangle occupies just 1.6% of the total area of the globe’s oceans, but represents 53% of all coral reefs and is home to 76% of known coral species and 37% of coral-reef fish species.

These coral reefs provide significant economic and social resources for the people of Timor Leste. And they underpin significant tourism potential, one of the few sectors capable of providing an economic substitute for the country’s heavy reliance on its depleting oil reserves. The marine pollution puts these resources at risk.

Reducing plastic pollution

In 2019, as part of its work in Timor Leste, Renew came across a local effort in Atauro to both reduce plastic pollution on the island and provide income-earning opportunities for the local community.

The initiative, Ekipa Tasi Mos Atauro (translates to Clean Ocean Team Atauro), is a social enterprise supported by environmentalist and Atauroan resident Barry Hinton, who runs eco-tourism lodge Barry’s Place on Atauro, aiming to raise awareness, educate and demonstrate positive environmental practices. Ekipa Tasi Mos Atauro’s work includes assisting the community to reduce their use of single-use plastic, while at the same time collecting, recording and, now, recycling plastic pollution from the marine environment that surrounds Atauro. Bernadette Davis, of the Australian-based Tangaroa Blue Foundation, was instrumental in helping get this initiative off the ground. Tangaroa Blue is an organisation dedicated to the removal and prevention of marine debris.

Setting up the recycling station

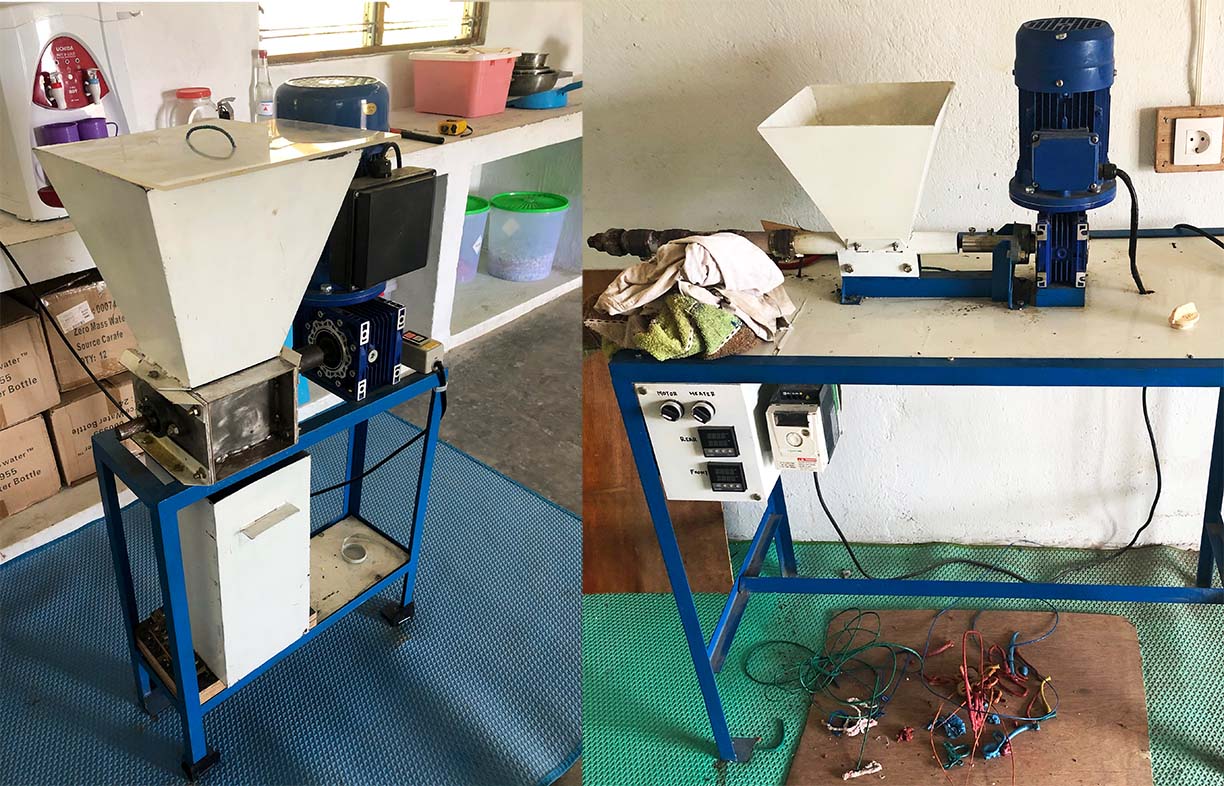

In mid-2019, Barry’s Place donated land, resources and a building to establish a marine plastics recycling station.

The group investigated several types of technology for small-scale recycling. They looked at Australian technology developed by the Plastic Collective (www.plasticcollective.co), but scant resources meant that the first set of machinery commissioned was based on the lower-cost open-source plans developed by Dave Hakkens’ Precious Plastic project (www.preciousplastic.com). These plans were adapted by Jeff Dusting, founder of Melbourne-based ‘for-purpose’ enterprise Plastic-As-A-Resource (www.plasticasaresource.com) which recycles plastic on a small scale in Australia.

Jeff engaged local engineers and fabricators to manufacture four recycling machines in Indonesia. These arrived and were installed at Atauro in October 2019. Together the four machines are used to create upcycled functional plastic products.

Local collection, and work

In late 2019 the local work began. Community members are paid to collect plastic waste from beaches and markets on the island. The plastics are sorted into their types and colours and this data is recorded in the Australian Marine Debris Database. Then the plastic pieces are washed prior to the recycling process.

Currently the Atauro project focuses on upcycling HDPE (2)—high-density polyethylene—such as bottle lids and rigid containers, which make up a large proportion of marine debris because they float well. HDPE has a low (180 °C) melting temperature and shrinks when it cools making it easy to remove from moulds.

Initial products produced include chalices, bowls, coasters and tiles, which are sold to tourists. The sale of one item provides a day’s wage for the community members who collect and process the plastic. In the months ahead, as the team becomes more skilled and new moulds are created, other items will be produced including rulers for local schools and construction beams and pipes for use in the production of furniture, guttering and other building materials.

Health and safety of community members is paramount. The first rule is that plastic isn’t burnt. When PVC is burnt, for example, dioxins are released which are highly toxic and can increase cancer, reproductive problems and immune system damage. PP and PE are the safest plastics to use because they are low in toxic compounds.

As the HDPE plastic is melted, rather than burnt, fewer toxic fumes are released making it safer for the community members operating the plant. Personal protective equipment is provided including heavy clothing, gloves, boots and industrial masks.

Powering the plant

The mini plastic recycling plant is currently connected to a small unreliable government-operated electricity grid. Electricity is only available from 8 pm to 7 am. This restricts the operation of the recycling plant to evening hours, which is inconvenient for community members who, understandably, prefer to be with their families in the evening. To make matters worse, due to regular breakdown of the diesel generators or lack of fuel, the electricity grid is often out of service for weeks at a time.

Atauro is blessed with an abundance of sunshine. Renew is therefore working with Ekipa Tasi Mos Atauro, Plastic-As-A-Resource and our local Timorese technical partner CNEFP to design an appropriate solar system for the site, source quality components and support the installation.

Noting that not all the plastic recycling machinery is used at the same time, the draft specification for the system uses 3.5 kW of solar panels, Victron control gear including a Multiplus-11GX 48 V, 3 kW inverter/charger, and 8 kWh of Power Plus Energy Eco Series lithium batteries (2 x ECO4840P units). The estimated installed cost of the system is $15,000.

Unfortunately, the current Covid-19 pandemic has slowed all our on-ground activities in Timor Leste, but this time provides an opportunity for us to raise funds for the solar system. If you would like to support us please go to renew.org.au/preciousplastic.

Further reading:

Community

Community

Game of life

The Adaptation Game is a new interactive board game that uses science and storytelling to simulate how you and your community can respond to the next 10 years of climate change.

Read more Reuse & recycling

Reuse & recycling

Community eco hub

Nathan Scolaro spends 15 minutes with Stuart Wilson and Michael McGarvie from the Ecological Justice Hub in Brunswick, Melbourne.

Read more Reuse & recycling

Reuse & recycling

Recycled hydronic heat

Renew’s sustainability researcher Rachel Goldlust gives us a view of and from the Salvage Yard.

Read more