Recycled hydronic heat

Renew’s sustainability researcher Rachel Goldlust gives us a view of and from the Salvage Yard.

As many of us in the colder parts are now aware, winter brings with its clear nights and frosty mornings an increasingly eye-watering energy bill that is vital to keeping our homes and families warm. There are many possible solutions.

First, it’s beneficial to create zones such that we only heat the part of the house we are using, make small but significant changes such as insulation and draught stopping, and then rug up and bear the 20-23% increase in electricity and 22-28% in gas costs this year alone. The alternative is to consider an efficient heating solution that can be offset by solar, that can endure some of the fluctuations in the energy market while keeping the lights on and the house warm.

Regular readers of Renew will be familiar with hydronic systems, with several articles pointing to their many positive attributes, and the ability to DIY some of the processes and materials. Hydronic systems, traditionally popular in Europe and parts of North America, heat water and move it through sealed pipes to radiators throughout the home and can be heat pump or solar boosted. There are also companies like Comfort Heat who design and supply hydronic underfloor heating systems, which rely on pipes laid in the concrete slab or screed to carry heated water.

Hydronic heating radiators operate as ‘heat emitters’ in each room, pushing out radiant heat. They can be individually adjusted and placed on a timer. Unlike forced-air heating systems, hydronic radiators don’t tend to stir up dust, making them ideal for medical conditions such as asthma. Many people prefer the feeling of radiant heat—that is both silent and non-intrusive.

With growing discussion focussed on household electrification, there is the inevitable refrain: “but the outlay is so high”. Indeed, changing out major appliances in our homes, and particularly adding in new pipes for hydronic heating, is often expensive and can be complicated when looking to change out an entire system like gas ducted heating.

Though the prices for heat pumps as a way of offsetting the cost of hydronic heat are coming down and the technology is continuously improving, there are calls to investigate the carbon footprint of renewable solutions that don’t involve installing new equipment fresh out of the box from China.

One enterprising salvage yard in Castlemaine, Victoria is looking to offset some of the cost by drawing on local solutions to the age-old problem of household heating. They are encouraging builders and home-renovators to consider recycled hydronic heating units as an energy efficient way of warming our homes, lowering our footprint, and bringing back some of the ‘can-do fix-it’ mentality to home renovations and energy upgrades.

I chatted to co-founder and manager of the Salvage Yard Anna Winneke on the value of reclaimed materials, and what it means for our renewable future if we don’t value the stuff we already have.

Rachel Goldlust: What is the Salvage Yard and what are the benefits of recycled materials?

Anna Winneke: The Salvage Yard has been in situ since 2010 and a going retail concern from 2015. It was a natural progression of our registered building business specialising in reclaimed materials. We had been working in Central Victoria as Pumphouse Design and Building Works since 2002, offering owner-builder support in the region, and the fervent creativity in our community gave us the confidence to set up the yard.

We consider the yard modelled around the old ‘builders’ yards that were commonplace in the middle of the 20th century and critical in lean times. We specialise in the sales of any material that a ‘builder’ might require, right down to hard-to-find hardware, dunnies, sinks, doors and windows, as well as other high-quality timber items. The era and clientele have shifted a bit, but the ethos is the same.

Apart from the material sales, our core focus is re-educating the public around the value of ‘making the effort’ to use reclaimed materials. In a time of great division of wealth and dwindling natural resources, we are concerned by how much the focus has shifted, generation to generation, from being proud to use our own labour to reuse, to the expectation that off-the-shelf ‘new’ will be readily available forever. Essentially, we are bothered by our ‘champagne taste, beer budget’ way of life that has become the new, wasteful normal.

We understand the roles of the developer and the demolisher, and as a society we are beginning to understand the shortcomings of our ‘waste’ industry, the finality of the ‘tip-face’, but nobody seems to have any answers for the nebulous space in between, and the opportunities for a renewed industry in re-use (I use the term ‘renew’ as this was not so long ago the norm).

Are there many yards out there like yours?

There are some great businesses in Victoria that have really invested in themselves to specialise in re-machining reclaimed timbers to create fabulous products. As we all know, timber is our greatest resource, and aged timber is amongst the most stable. There is a swag of folk working to empower and promote the benefits of re-using existing materials in new builds. There are a few older yards that cover all the bases, but they are getting fewer, and are often unable to be accessible to the broader cross section of our community. Of the scale and diversity? We don’t know of any other yards like ours!

So, what is your relationship to hydronic heating systems?

In our home in Fryerstown, we had second-hand cast iron radiators running through a wetback in our Jetmaster open fire. The radiators heated beautifully to a low warmth which took the edge off all the peripheral spaces in that old stone house.

The great thing about cast iron panels is that although slower to heat, they retain their heat for a long time. If you have them hooked up to a source like a wood heater, they will continue warming the spaces long after the fire goes out!

We have amassed quite a collection of all types of hydronic panels for sale, from the cast iron ones in various forms (rarer as they are generally early to mid-century), to pressed steel (still commonly available) and tubular steel. More and more we are seeing contemporary European-style cast iron panels (still available new and hugely expensive) with newer builds coming down.

And what made you get involved in the demolition of the old Castlemaine hospital nurses’ quarters?

Any local demolition interests us, apart from the fact that these old agriculturally-built buildings are full of well-made materials, and if we didn’t get involved, then everything needs to be trucked off to tips or processing plants in other shires. Considering that our shire has a salvage yard willing to lighten that load, it’s kind of nuts that we don’t get contacted more often!

Regarding reliability, the units are purely vessels to hold water. Their reliability as a vessel comes from whether they are cracked. Like a car radiator, these are pressure tested by a plumber before being connected and fitted off. Beyond the vessel, I guess the reliability of the system would come down to the plumbers that install it, and the quality of their joins!

What do you think needs to happen for more people to a) get hydronic heating and b) install older units?

The barrier to using second-hand anything, including hydronics, are the optics and the message from the young builders to their clients. When we live in a world that is sold ‘luxury’ as a norm, anything second-hand can be viewed as ‘grubby, lesser, scum baggy, quaint’ and seen as a choice for young people or those struggling to obtain that vision of luxury. It’s less about budget these days, as wages for processing materials are quickly outstripping the notion that second-hand is cheap. Like everything, it comes down to choice.

Hydronic panels are no different. If demolition practices aren’t legislated to protect the materials, then panels are scrapped, which means availability is going to be an issue. But even if buildings were being forcibly deconstructed, unless the education keeps pace with the salvage, there would be a glut of materials, and no empowered young builders to use them, or recommend the use to their clients!

We are keen to spread the word that these units still have value. We want to see more empowered contractors who do have a huge influence on the confidence of their client base. If a contractor is telling his client to not bother with second-hand, then of course the misinformation spreads.

It is more common these days to meet disempowered people in our yard longingly wanting to incorporate a leadlight bay window into their new build, but too scared to push the point with their contractor whose response is, “Nahhh… too hard”. Clients are too scared to lose their long-awaited contractor, so they compromise and go without.

How to retrofit recycled hydronic panels

Morgan Williams, who runs a design studio in Daylesford, Victoria, bought eight old steel radiators from a salvage yard in Ballarat for his commercial property, and then home, around 15 years ago. He loved the look of the raw metal, the fact that he was using a recycled material, and later discovered that he prefers the way the heat makes him and his family feel. Comparing the heat at home to their reverse cycle air conditioners, he notices the way hot air makes his eyes itch in a way radiant heat does not.

Morgan speaks highly of both the aesthetic and function of the five radiators he had installed in his commercial property, but says the older ones are more reliable, and much heavier to move around. Newer and smaller models can also be broken by too much weight, and the metal holds less heat for less time than the cast iron version. Morgan had three to four installations over the years and each time the plumbers had no issue pressure testing, cleaning out the old gunk, changing the valves and regulators, and replacing the coolant in each unit.

Before deciding on whether recycled steel or cast-iron panels would work for your new build or renovation, it’s best to chat to someone who has some knowledge of hydronic heating or has worked with them in the past, before contacting a gas fitter or plumber to conduct the necessary pressure test. You can also get the unit sandblasted and painted to fit in with your build or renovation but be careful of cracking the shell (bead blasting is a less risky cleaning option—Ed). It is also worth chatting with your plumber to decide whether your heating unit (heat pump or solar) can accommodate the heating load of the panels, and the size of the entire system.

Further reading

Efficient homes

Efficient homes

Tradies and the transition

Do we need as many tradies for electrification as many think? Not if we are innovative, writes Alan Pears.

Read more Efficient homes

Efficient homes

Double glazing on the (very) cheap

Do we need as many tradies for electrification as many think? Not if we are innovative, writes Alan Pears.

Read more Efficient homes

Efficient homes

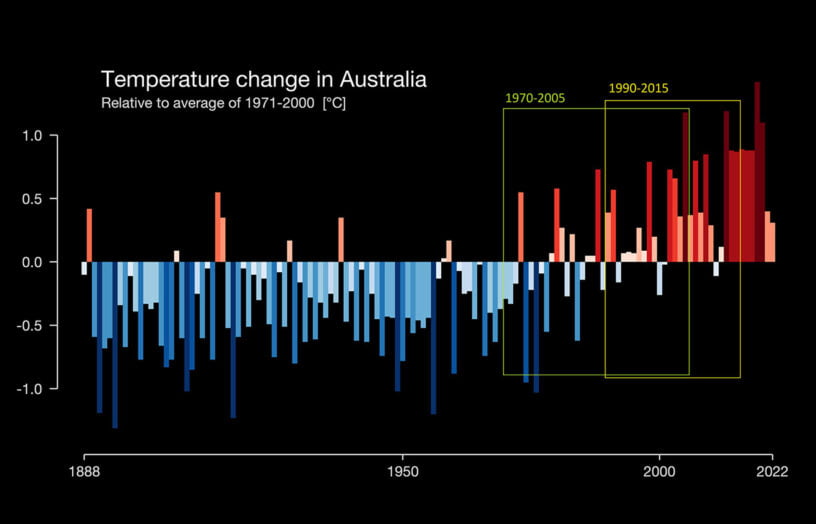

Building for a changing climate

Are we building homes for the future, or for the past? Rob McLeod investigates how climate change is impacting home energy ratings and the way we build our homes.

Read more