Greenhouse gas footprint: What we do and don’t know about gas

Do you want to know the greenhouse footprint of Australian gas? Tim Forcey says, “how would we know?” — because no one is keeping track.

This article was first published in Issue 144 (July-Sept 2018) of Renew magazine.

Energy and environmental planners like to do calculations and compare alternatives. Questions researchers might explore include: Which is cleaner: electricity made from coal or gas or renewables? What is the greenest way to heat your home, have a shower or cook spaghetti?

But there is a problem when it comes to evaluating the greenness of gas. Such comparisons need to be built on data. And, unfortunately, as we found recently in research at the University of Melbourne (1), although Australia may produce more fossil gas than nearly every other country, when it comes to digging up information around the greenhouse footprint of Australian gas, particularly unconventional gas, data is in short supply.

The greenness of gas depends significantly on how much is released into the earth’s atmosphere. Fossil gas predominantly consists of methane which is a powerful greenhouse gas—with worse climate impacts than carbon dioxide (see box). Our research found that if just 3% of the produced gas is released into the atmosphere, the climate-change impact of this released methane is equivalent to or worse than the climate impact of burning (and thereby converting to carbon dioxide) the other 97%.

It is critical, therefore, that we know how much gas is released during production and other stages.

Unconventional vs conventional gas

We’ve all heard of fracking and coal seam gas, but it can be easy to miss just how much these ‘unconventional’ gas production methods have escalated in recent years in Australia. There is some real (measured) data on emissions from conventional gas extraction, but these measurements can’t simply be applied to unconventional gas.

Data on Australian unconventional gas emissions—an empty slate

As we wrote in our report, despite Australian government greenhouse gas reporting requirements having been established in 2009 and Australia’s unconventional gas industry operating at significant scale in 2010 and rapidly expanding since, there has as yet been no comprehensive, rigorous, independently verifiable audit of gas emissions from unconventional gas.

Indeed, to quote CSIRO (2), “reliable measurements on Australian oil and gas production facilities are yet to be made.”

Despite our 2016 report and similar findings by the CSIRO dating back to 2014 and earlier, we are now in 2018 and nothing has changed.

ReNew readers are probably aware that Australia reports greenhouse gas emissions to bodies such as the United Nations. You might then ask: “How is this data blindspot possible?”

Our ignorance persists because government regulators do not require oil and gas companies to actually measure emissions as a basis for accounting and reporting. Rather, assumptions and simple factors may be used.

Zeroing out gas field emissions

For example, when it comes to coal seam gas fields, the factors used to calculate emissions from the extensive network of lines, compressors and pumps which connect producing gas wells to transmission pipelines are “set at zero” (1). In other words, these emissions are ignored.

Likewise, ‘migratory’ emissions, such as might occur when gas migrates beneath the ground to reach the surface at some distance from gas production operations, are also assumed by the gas industry ad government regulators to be zero.

As part of the research for the University of Melbourne report, I travelled to the Queensland gas fields equipped with a $137,000 methane-sensing infrared camera. This allowed me to ‘see’ unmeasured amounts of methane being continuously vented into the atmosphere from the water pipelines that are associated with coal seam gas production (3) (see images above).

At other times, the burning-off of gas—for operational reasons—in the gas production fields is clearly visible from elevated flares burning day or night.

The 2014 scrapping of carbon pricing in Australia is one reason that Australian authorities are allowed to ignore these gas field emissions.

What’s that smell?

Have you ever smelled gas in your street? If so, this is from leaking gas pipelines, meters and other gas equipment. If you do smell gas leaks, please report them to your gas distribution company or your local council. Indicating the poor state of repair of gas networks in some cities, a 2012 study using vehicle-mounted infrared sensors identified thousands of gas leaks on the streets of Boston, Massachusetts, USA (see photo).

Leaks of gas (methane) all along the chain of production, processing and compression, interstate pipeline transmission, reticulation pipelines and end-use appliances all add significantly to the greenhouse gas burden of gas.

Who’s the cleanest of them all?

Proponents of Australian fossil gas routinely claim that gas can be “cleaner than coal”, “the cleanest fossil fuel” or “a low-carbon form of energy” despite there being no measured and published data to support their claims.

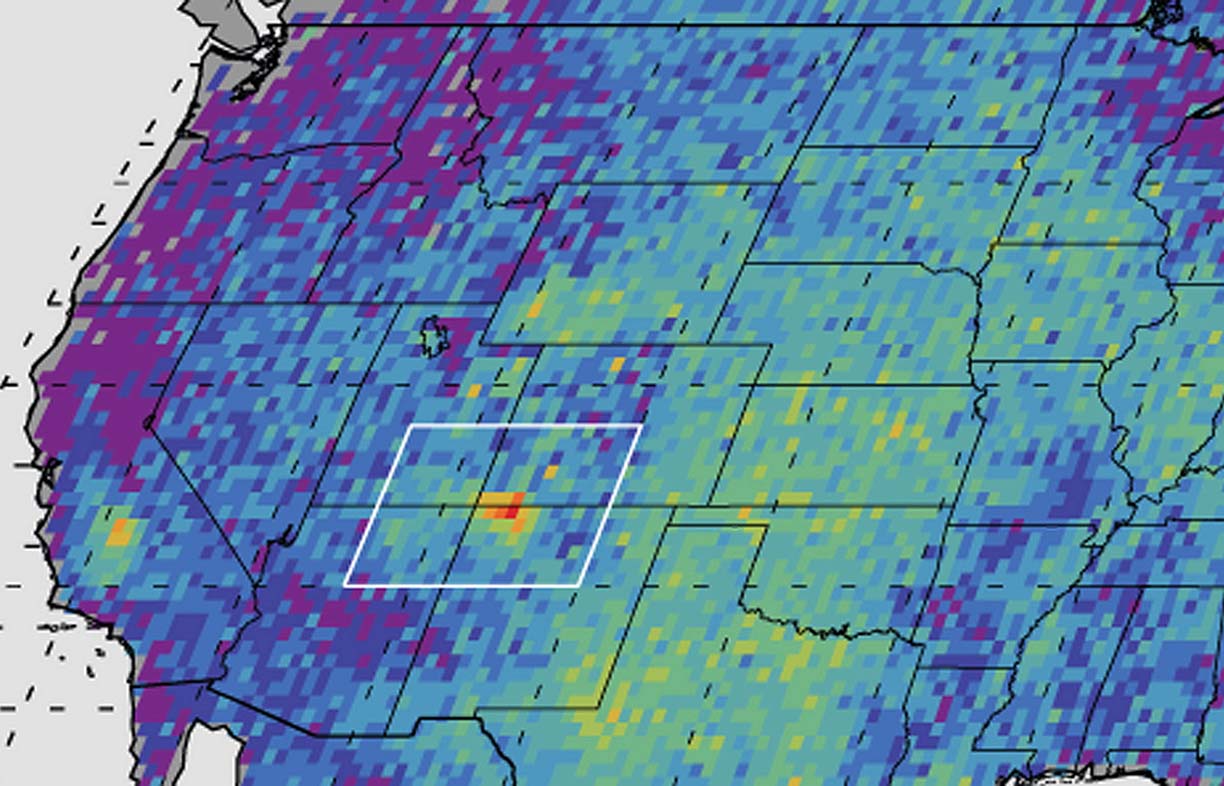

Although substantive methane emission measurements are not being performed in Australia, under the Obama administration significant progress was made in (or, rather, above) the unconventional oil and gas fields of the USA. Studies there found methane emissions ranging from 2% to 17% of total gas production (1). The amount of methane emanating from the US’s largest coal seam gas region is so large it could be seen by a satellite (equipped with the appropriate methane-sensing equipment).

NASA-led technology now exists which can rapidly identify methane emission sources and quantify emission rates, using instruments mounted in planes. Similarly, drone-based methane sensors are also available. In the future it will be harder for methane emissions to go by undetected and unreported (5).

Taking action in your all-electric home

So what is to be done by energy planners or anyone else wishing to compare the pros and cons of different energy sources? Until we can rely on systematic emission measurements conducted within or above Australian oil and gas fields, planners should consider the full range of practices that might be going on out there, using as a guide measurements from above US unconventional oil and gas fields—the only place where data has been collected so far. Or, since in my view there is no chance that fossil gas is a clean, green fuel, we should just focus on energy efficiency measures and fuel-switching from fossils to renewables.

As we have seen demonstrated at Sustainable House Day and among members of the Facebook group My Efficient Electric Home, many Australians aren’t waiting around for emissions data and comparative analysis to appear from gas companies or government regulators before taking action in their own homes. For reasons including economic, environmental, aesthetic, comfort and convenience, people are finding that it makes sense to ditch gas and rely on renewable sources of heat and electricity (6).

- ‘A review of current and future methane emissions from Australian unconventional oil and gas production’, D Lafleur, T Forcey, M Sandiford, H Saddler, University of Melbourne Energy Institute, October 2016; available here.

- ‘Field measurements of fugitive emissions from equipment and well casings in Australian coal seam gas production facilities’, S Day, M Dell’Amico, RA Fry, H Javanmard Tousi, CSIRO Australia, 2014.

- ‘Infrared video-recording methane emissions in the Queensland coal seam gas fields’, T Forcey, February 2017; available here.

- ‘Four corners: the largest US methane anomaly viewed from space’, E Kort et al., Geophysical Research Letters, 2014.

- ‘Airborne methane remote measurements reveal heavy-tail flux distribution in Four Corners region’, C Frankenberg et al, Proceedings of the National Academy of Sciences, vol. 113, no. 35, August 2016.

- ‘Beyond solar PV—renewable heat and why we need it’, T Forcey, Renew 142, January–March 2018.

What the frack is going on? Unconventional ways to produce oil and gas

Below is an extract from a presentation by Tim Forcey delivered at the University of Melbourne on 7 May 2018.

In New South Wales, some people want to destroy the Pilliga State Forest in order to sell coal seam gas to overseas buyers. In Queensland, where the gas horse has already run out of the barn, industry expansion continues unabated as they aim towards drilling 40,000 wells. In the Northern Territory, the government recently decided to lift a previous moratorium on fracking. In Western Australia, the government is considering the future of their fracking moratorium. In South Australia, new oil and gas fields are being developed right within the world-famous Coonawarra wine-producing region near the Limestone Coast, as well as in central desert regions. In Victoria, where many people worked to deliver legislation that prohibits fracking for onshore oil and gas, the billionaire Gina Rinehart and Lakes Oil are suing the Victorian government in an effort to have that legislation overturned.

In the ‘good-old’ days in the oil patch, meaning from the 1920s right up into the 1980s, an oil and gas company could drill one well straight down to tap into a naturally pressurised, highly porous and permeable sandstone or limestone rock structure. And from that one well, with no other assistance, up would come significant volumes of oil and/or gas.

In those days, a single well or two or six could light up an entire city or feed an entire liquefied natural gas (LNG) export plant. However, the decades passed and many of those conventional oil and gas reservoirs were discovered and, over time, depleted. So what could the oil and gas companies do next in order to stay in business?

This is where ‘unconventional’ oil and gas production techniques came in. Below I describe four of these techniques, including, of course, hydraulic fracturing, or fracking.

Image: normaals via iStock

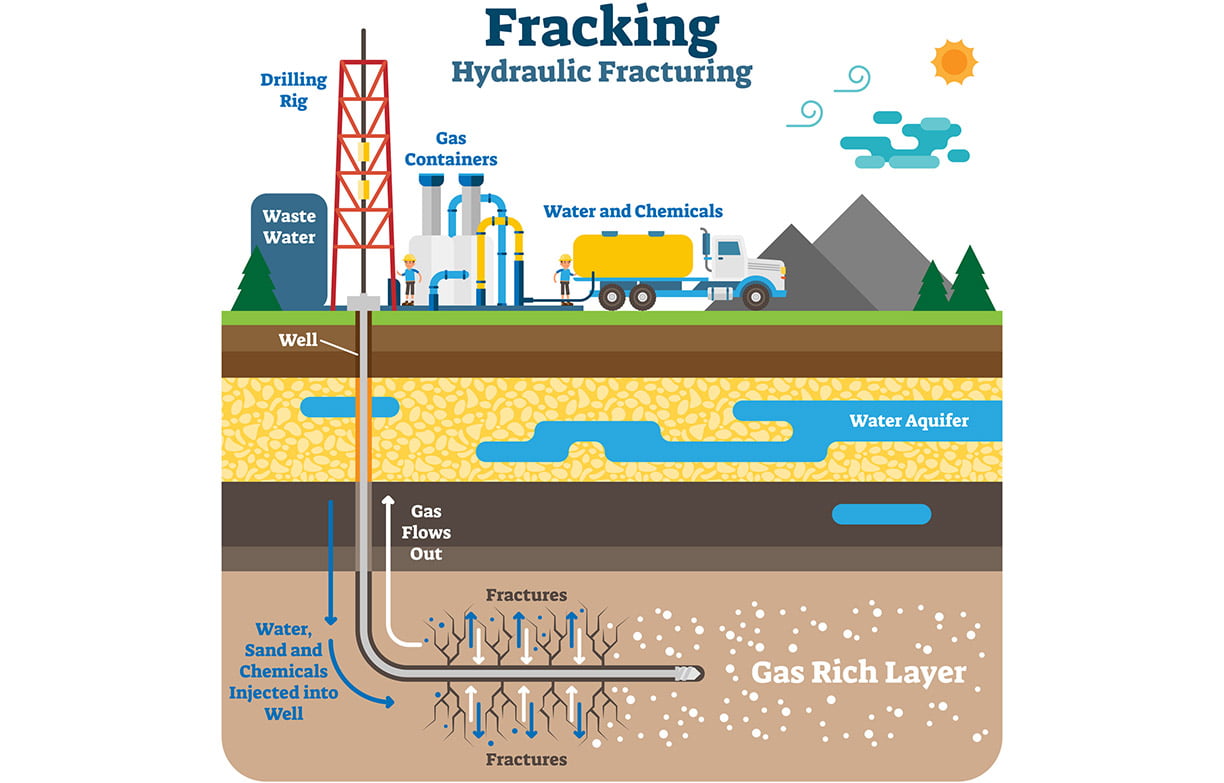

First, let’s consider horizontal directional-drilling, because without this there wouldn’t be much fracking.

These days, instead of drilling straight down, wells can deviate as far as 15 kilometres away from the drilling rig—like drilling from Melbourne University to Tullamarine Airport. In 1994, horizontal drilling was used to drive an oil well under England’s Windsor Castle. Putting aside the need to drill under heritage landmarks, for what other reasons might an oil well be drilled horizontally?

These days, oil and gas companies are left chasing thinner and skinnier reservoirs. By running a drill down and across horizontally through these skinny reservoirs, more pathways can be set up for draining the hydrocarbons from this type of reservoir.

A second reason is because the producer might want to drill a multitude of wells from a single well pad location with just one drilling rig. As many as 36 horizontally deviated wells can be drilled from one location using so-called ‘Octopus’ technology.

After a horizontal well has been drilled into a not-so-porous-nor-permeable rock reservoir, which might be referred to as ‘tight’ sandstone, shale or even a coal seam, how can hydrocarbons be made to quickly flow out of that kind of rock?

Enter the invention of hydraulic fracturing, where, under great hydraulic pressures, large volumes of fluids, chemicals and fine sand are injected into the rock. The aim is that the rock reservoir is fractured, thereby opening up many pathways for oil and gas to flow towards the wellbore.

Concerns with fracking include contamination of underground drinking water supplies, disposal of waste, man-made earthquakes, poisoning of surface water, soil contamination, air pollution, greenhouse gas releases, trucking movements, social impacts and more.

With unconventional oil and gas, the target rock reservoir is not that productive. So it must be worked quite hard to get something useful out of it. Some say oil companies are left ‘scraping the bottom of the fossil fuel barrel’. A large number of wells are needed to tap into any interesting volume of oil and gas.

The coal seam gas producers in Queensland talk about eventually drilling 40,000 wells. In the USA, there are reportedly 1.7 million active oil and gas wells.

There are many concerns about pin-cushioning the countryside with oil and gas wells, and cross-hatching landscapes with pipelines, roads, water-holding ponds and other infrastructure. For example, how much care and attention will an oil and gas company spend on each of these many wells and each piece of infrastructure?

If you want to produce gas not from shale or tight sandstone but rather from that other unconventional target, coal seams, you must first pump out the water contained in those coal seams.

The three techniques described above (horizontal drilling, fracking, and dense-and-widespread well deployment), are all used in the coal seam gas fields to assist with removing water and then gas.

Community concerns with pumping water from coal seams include what do you do with the water you have pumped out, as it might contain salts and other contaminants. What impact is there on farmers and others when you draw down the water table? And while you are busy trying to coax gas to come into your wellbore—what if it decides to bubble up somewhere else?

This article was first published in Issue 144 (July-Sept 2018) of Renew magazine.

Related articles

Pears Report

Pears Report

Energy forecasts, hydrogen hype and questions of progress

Alan Pears gives us his round-up of the main energy issues this quarter.

Read more Pears Report

Pears Report

Energy costs, climate impacts and quality of life

Alan Pears brings us the latest news and analysis from the energy sector.

Read more Pears Report

Pears Report

Fossil fuels, efficiency and TVs

Alan Pears brings us the latest news and analysis from the energy sector.

Read more