MVHR buyers guide

As homes become more airtight, the need for mechanical ventilation grows. Heat recovery systems bring in fresh air with minimal heat loss. Joel Seagren explains how they work and what to look for.

Mechanical ventilation with heat recovery (MVHR) is used to deliver reliable ventilation to maintain excellent indoor air quality in occupied buildings. It supplies fresh filtered air into the building and simultaneously extracts damp, stale or contaminated air, without the energy, comfort and noise issues that can arise with open windows. Mechanical ventilation can be thought of as providing continuous fresh air in a controlled manner. That is, you can know exactly how much fresh air you’re getting with mechanical ventilation—unlike when relying upon opening windows. These systems are designed to operate continuously, while consuming very little power (usually less than 40 W).

The Australian Building Codes Board has produced a handbook that provides information on potential contaminants in indoor air, including sources and acceptable levels (bit.ly/ABCB_IAQ, p. 24). In typical homes, these might include CO2 from occupant respiration, gas cooking and unflued gas heaters; particulates such as PM10 and PM2.5 from cooking, tracked in or from carpet degradation; and volatile organic compounds (VOCs) from synthetic products such as carpets and laminates, cleaning products or even cosmetics. There are some generally accepted standards for good indoor air quality and MVHR systems are designed to meet these.

Why would you need an MVHR system?

Natural ventilation through open windows and doors isn’t always going to be enough to ensure good indoor air quality, as this is dependent on variables such as window size and location, occupant behaviour, wind speed and temperature.

An important factor to consider is the building airtightness. Typically, Australian buildings have been constructed to a very low level of airtightness (>10 air changes per hour—ACH—at 50 Pa), so ventilation using windows has been supplemented by air leakage.

When you improve airtightness (to improve energy efficiency of the building and reduce moisture build-up in walls and the roof space), planned ventilation becomes more critical. It’s difficult to stipulate an airtightness figure at which MVHR becomes beneficial, due to variables such as local wind speeds and window areas, but a rough rule of thumb is that you should starting considering MVHR if you expect to reach airtightness levels below 5 ACH at 50 Pa, and definitely look to include it if you are targeting lower levels, such as the Passive House standard of 0.6 ACH at 50 Pa. It is very difficult to integrate effective ducted MVHR systems once construction has started, so this consideration should be part of the design process for a new building or extension.

Does the presence of an MVHR system mean that you need to keep your windows closed at all times? Certainly not. You can open up your house whenever it is comfortable to do so. The reality is that for most locations there are parts of the year where it is too hot, too cold, too noisy, too dusty or too risky to leave your windows open for long periods.

Components of an MVHR system

There are two types of MVHR system: centralised, which use a single large MVHR unit with a duct network, and decentralised, which use multiples of small through-wall MVHR units without ductwork.

Centralised ducted MVHR systems will generally outperform decentralised ones due to the ability to locate grilles for the best ventilation outcome; for example, you can have an extract grille in the ceiling above a shower. The benefit of decentralised units is that they can be integrated without needing to allow space for ductwork. This is particularly useful in retrofit projects.

– Centralised (or ducted)

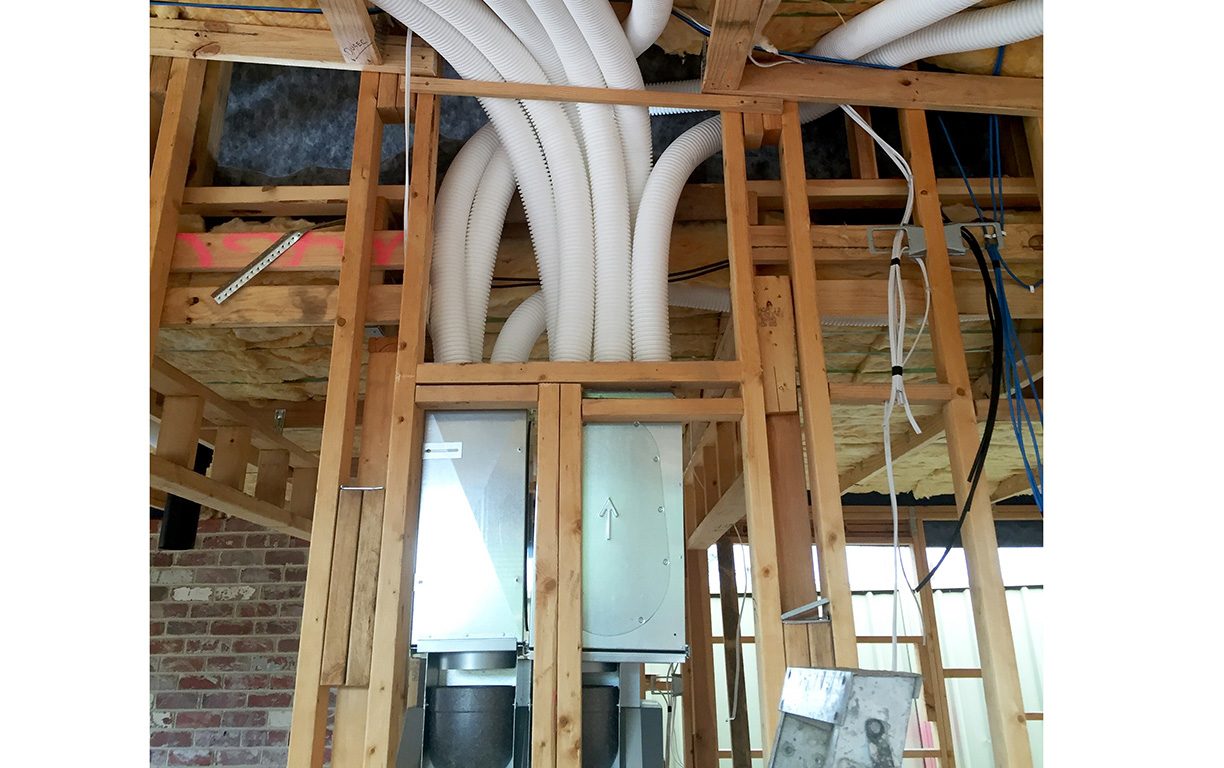

In a centralised system, there is an MVHR unit (sited inside your home) with ducting runs from that. The preferred approach uses a radial design for the ducting, with a central manifold. This makes it possible to more accurately control how much air flows to/from each grille as different rooms require different flow rates. It also prevents noise transmission from one grille to the next, when compared to branched systems. Usually the system supplier, or an experienced system designer, will determine the optimum configuration for each installation.

The MVHR unit is an insulated box that houses the fans, heat exchanger and any controls and filters. The controls will differ by brand, but usually include the fan speed (which in turn sets the amount of airflow through the system) and the bypass temperature (the temperature above which the extracted air bypasses the heat exchanger so as to not unduly heat the incoming air if the indoor temperature is already above the outdoor temperature—known as night cooling).

The systems are normally set up so that air is extracted from ‘wet’ rooms such as the kitchen, bathroom and laundry, then passed through the heat exchanger, transferring heat to air coming in from outside. Importantly, the outgoing stale air and incoming fresh air do not mix—all the heat exchanger is doing is allowing the movement of heat from the warm air stream to the cool air stream. In cool climates the direction of heat transfer will be from the warm extracted air to the cool incoming air. This now warmed air then flows to other rooms, such as the lounge room and bedrooms. This ensures there is airflow through the entire home. In hot climates or in summer, heat transfer will be in the reverse direction.

Although the unit isn’t particularly noisy (around 45 to 55 dB is the likely noise level for a good unit, similar to or just slightly higher than the noise from the internal unit of an air conditioner), it’s best if this is in a less noise-sensitive area such as a laundry and away from bedrooms and living areas. A well-designed system will be less than 30 dB at the room supply grille, which is barely audible.

The internal ductwork is typically not insulated so must run inside the building thermal envelope, either below the insulation layer in the ceiling, or above it in the floor. The size of the duct work varies between different systems and airflow volumes, but typically internal distribution ductwork is 70 to 90 mm in diameter. Avoid lightweight flexible duct (the foil type) as it tears easily, is difficult to connect in a reliable airtight manner and has high airflow resistance due to the internal ridges. Instead use a semi-rigid or rigid ductwork system.

Other components include silencers and attenuators used to ensure noise level in rooms is reduced to acceptable levels, grilles and boost switches (for additional airflow in bathrooms, toilets and the kitchen). Altogether quite a bit of volume can be required for the MVHR unit, manifolds and ductwork. Ideally the fitting of this equipment in a renovation or new build should be considered early on to ensure a simple and optimal installation.

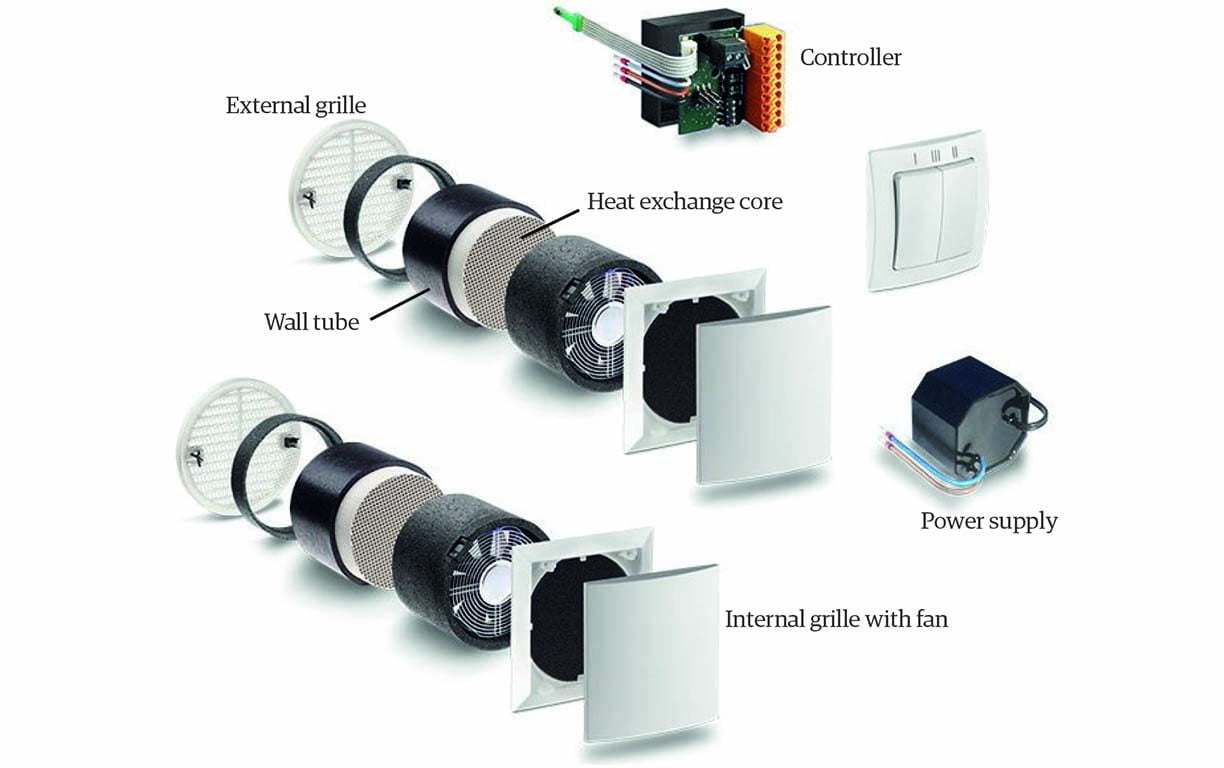

– Decentralised (through-wall MVHR unit)

Single point

In these units, air is simultaneously supplied and extracted via a partitioned wall tube.Airflows cross over (but never mix) through the heat exchanger and heat is transferred continuously from one airflow to the other.

Two point (paired units)

With this style of unit, two units work as one system, whereby one extracts air while the other supplies air—there is no classic heat exchanger like in the single point units or the centralised systems. As air flows through the units, heat is extracted and stored in a ceramic core—a block of ceramic with many air passages through it. Because the core will saturate with heat quite quickly, these units reverse direction every minute or so, allowing the heat that has been stored in the ceramic core to be transferred into the supply air stream.

For example, in winter, outgoing air loses heat to the core, which warms up. When the unit reverses and starts drawing in air from outside, the cold incoming air is heated by the warm core. The opposite is happening in the other unit in the pair—when the core

in one is heating up from the outgoing air, the other core is warming up the incoming air. This allows each pair of units to provide continuous airflow into and out of the home, while recovering most of the heat.

In summer, incoming hot air heats the core, becoming cooled as it enters the home. The core is then cooled down again by outgoing air on the reverse cycle.

Heat and energy recovery

There are two types of MVHR exchanger cores.

– Heat recovery

Heat recovery heat exchangers transfer heat from one air stream to the other, without allowing moisture transfer. This means they are well suited to climates where summer humidity levels are reasonably low (such as locations south of Sydney). Good test reports will provide a heat recovery performance figure for the entire MVHR unit (as opposed to just the heat exchanger which can be quite misleading).

– Energy recovery

Energy recovery exchangers provide both heat and moisture recovery, allowing moisture to be transferred from the incoming air stream to the outgoing exhaust stream during humid summer conditions, thereby providing dehumidification, which can increase occupant comfort and reduce the risk of mould. They are well suited to higher humidity locations (such as Queensland). This moisture transfer can also be used to provide some needed winter humidification in cold dry climates, but this application is fairly limited in Australia.

Ask your supplier about their experience in particular locations using heat recovery and energy recovery cores.

Sizing and energy usage

Typically, residential projects require between 0.3 and 0.4 air changes per hour to ensure healthy indoor air quality (note this is about actual air changes in the house in normal usage, rather than the rate measured at 50 Pa using a blower door test as used for certification). An MVHR should provide for this along with a boosted airflow rate for when a shower, toilet or kitchen is in use or there are a larger than normal number of people in the house.

In order to reliably achieve these requirements and keep noise levels and efficiency at acceptable levels, an MVHR should, as a rule of thumb, be sized so that the standard airflow rate is not more than about 60% of the maximum airflow rate. Typically the maximum airflow rate is the name plate volume; for example, a Zehnder Q350 MVHR unit has a maximum airflow rate of 350 m3/h.

Good suppliers will assist you with sizing, but to provide a rough example, a building with a floor area of 250 m2 and a ceiling ‘design height’ of 2.5 m, has a volume of 625 m3 (the design height of 2.5 m is used when designing a system as not all contaminant sources increase with ceiling height, such as VOCs from carpets). To provide 0.35 air changes per hour, you would need a standard airflow rate of around 215 m3/h. In this case it would be just acceptable to use a unit with a maximum airflow rate of 350 m3/h. Individual room airflow rates are also considered in good design, but this example provides a starting point for sizing an MVHR unit.

Units will generally have hardwired switches or remote RF (radio frequency, i.e. radio controlled) switches to control the boosting of airflow rates for short periods in bathrooms, toilets and kitchens when needed. Hardwired switches are more reliable but need to be planned during building design.

A high quality Passive House certified centralised MVHR system in a 250 m2 building will use about 35 watts during normal operation. This would add less than 1 kWh/day to your energy consumption but could reduce your heating and cooling energy by up to 3500 kWh annually (when compared theoretically to open windows that deliver equivalent ventilation with an average indoor to outdoor temperature difference of 6 degrees).

Power consumption for low-performance systems could be as much as 100 watts for the same airflow. In either case, the heating and cooling energy savings exceed the energy required to operate the MVHR.

Decentralised systems can use up to around 10 watts per fan unit, although the average is less than half that. Total power draw will depend on how many fan units you install, the minimum being two for paired systems or one for single point systems.

What to look for

I’d recommend looking for a unit which has been tested to a recognised standard for heat recovery efficiency, noise level and energy consumption. Established MVHR test standards include Passive House Certification, Eurovent and European ErP Directives (Regs 1253 and 1254).

A good MVHR unit will have excellent insulation and both the unit and the ductwork should have an airtight design. The presence of features such as rubber O-rings indicate effort has been made to ensure a robust airtight design. While it can be hard for a potential buyer to ascertain the build quality of a unit, those that meet the test standards will almost inevitably have these features. The Passive House Component Database is one place to check for quality systems (database.passivehouse.com/en/components).

You’ll also need to find a supplier to help you with designing the system you need for your home, whether that’s a single decentralised unit for your living area or a fully ducted system for your whole house. Many of the biggest and most reputable suppliers in Europe now have Australian distributors, so finding local suppliers both for the initial installation and ongoing support is not as difficult as it once was.

Filters and maintenance

There is generally minimal ongoing maintenance or monitoring of these systems. The most frequent maintenance is to check the filters on the heat exchanger every six months or so. Often this can mean simply giving the filters a quick vacuum to remove dust. Depending on how dusty the neighbourhood is the filters will usually need to be replaced every 6 to 12 months. Replacing the filters is a simple task for the owner and is probably easier than changing a vacuum cleaner bag. The cost of filters will vary depending on the MVHR brand, but as a rough guide may cost in the order of $100 per year.

It may be necessary to clean additional filters provided in the manifold or vents, although the need to do this will vary based on the manufacturer and the local air quality.

Cost, warranties and reliability

Like most equipment, price is roughly a reflection of quality of build, performance and support and service.

For the 250 m2 building example, expect prices for full ducted systems to range from $7000 to $12,000. Given this broad range ask your supplier what’s included in their offering, and what the cheaper or more expensive options might include.

Decentralised systems range from $1200 to $2000 per unit, remembering you may need two to four sets of these to provide similar overall ventilation levels to a ducted system in our example.

Typical warranties range from one to two years, which is unfortunately short. It doesn’t necessarily reflect the quality of the products, but rather industry standards. Components that could fail include fans, control boards and bypass actuators. However, I’ve seen many 10-year-old high-quality units happily operating in Australia and New Zealand.

Power failure or MVHR unit failure isn’t necessarily a significant concern, as it will take a reasonable amount of time (more than one day) before contaminants reach an immediately harmful level even in a very airtight building. Opening some windows offers a temporary solution should this happen.

| Make | Model | Type | Max airflow (m3/h @ 100 Pa) | Certification | Heat recovery % | Noise (dB) | Energy consumption (Wh/m3) | Australian distributor |

|---|---|---|---|---|---|---|---|---|

| Aerofresh | Aerofresh 180 | Centralised | 180 | ErP 1253&4/2014 | 82% | 50 | 0.41 | Fantech info@fantech.com.au www.energyrecovery.com.au |

| Aerofresh 240 | 240 | 80% | 53 | 0.39 | ||||

| Aerofresh 500 | 500 | 86% | 52 | 0.27 | ||||

| ATREA | DUPLEX Easy 250 | Centralised | 250 | Passive House | 85% | 60 | 0.44 | Logikhaus info@logikhaus.com.au www.logikhaus.com.au |

| DUPLEX Easy 300 | 300 | 88% | 60 | 0.37 | ||||

| DUPLEX Easy 400 | 400 | 88% | 61 | 0.39 | ||||

| Brink | Brink Flair 325 | Centralised | 325 | Passive House | 91% | 45 | 0.21 | Plus Energy Living info@plusenergyliving.com.au www.plusenergyliving.com.au |

| Renovent Excellent 300 Plus | 300 | 84% | 47 | 0.26 | ||||

| Renovent Excellent 400 Plus | 400 | 84% | 52 | 0.29 | ||||

| Renovent Sky 150 Plus | 150 | 84% | 44 | 0.35 | ||||

| Renovent Sky 200 | 200 | 84% | 48 | 0.35 | ||||

| Renovent Sky 300 | 300 | 85% | 48 | 0.31 | ||||

| Lunos | Lunos E2 | Decentralised | 38 | N/A | N/A | 42 | 0.16 | Laros Technologies office@laros.com.au www.laros.com.au |

| Lunos Ego | 45 | N/A | N/A | 45 | 0.2 | |||

| Maico | WS160 | Centralised | 160 | Passive House | 79% | 48 | 0.38 | RecoveryVent |

| WS170 | 160 | 86% | 38 | 0.37 | ||||

| WS320 | 320 | 92% | 47 | 0.24 | ||||

| WS470 | 470 | 90% | 52 | 0.29 | ||||

| WR600 | 600 | N/A | N/A | N/A | 0.31 | |||

| Sabiana | ENY-SP-180 | Centralised | 180 | Passive House | 88% | 39 | 0.25 | Logikhaus info@logikhaus.com.au www.logikhaus.com.au |

| ENY-SP-280 | 280 | 88% | 45 | 0.25 | ||||

| ENY-SP-370 | 370 | 88% | 47 | 0.26 | ||||

| ENY-SP-460 | 460 | 89% | 51 | 0.31 | ||||

| Stiebel Eltron | LT50 | Decentralised | 54 | N/A | N/A | N/A | 0.35 | Stiebel Eltron |

| LWZ 70 E | Centralised | 175 | N/A | N/A | 46 | N/A | ||

| LWZ 170 E Plus | 300 | Passive House | 84% | 47 | 0.26 | |||

| LWZ 370 Plus | 400 | N/A | N/A | 54 | N/A | |||

| Systemair | SAVE VSR 300 | Centralised | 350 | Passive House | 78% | 51 | 0.35 | Laros Technologies office@laros.com.au www.laros.com.au |

| SAVE VSR 500 | 600 | 80% | 57 | 0.38 | ||||

| SAVE VTC 200 | 250 | 90% | 50 | 0.34 | ||||

| SAVE VTC 300 | 350 | 78% | 47 | 0.31 | ||||

| SAVE VTC 700 | 850 | 77% | 50 | 0.22 | ||||

| SAVE VTR 300 | 350 | 78% | 48 | 0.38 | ||||

| SAVE VTR 500 | 600 | 80% | 56 | 0.38 | ||||

| Zehnder | CS50 | Decentralised | 50 | Passive House | 80% | 40 | 0.3 | Fantech info@fantech.com.au www.energyrecovery.com.au |

| CA70 | 70 | 85% | 44 | 0.24 | ||||

| CA180 | Centralised | 180 | 82% | 43 | 0.27 | |||

| CA200 | 200 | 92% | 49 | 0.42 | ||||

| Q350 | 350 | 90% | 43 | 0.24 | ||||

| Q450 | 450 | 88% | 47 | 0.21 | ||||

| Q600 | 600 | 87% | 51 | 0.24 |

How a heating and cooling system interacts with MVHR

When selecting a heating or cooling system, it’s important that it only recirculates air to be compatible with an MVHR system. Think of the MVHR managing the introduction of outside air, and heating and cooling systems controlling indoor air temperatures.

Compatible choices include high efficiency split system units and radiant or hydronic options. Evaporative air conditioners are generally not compatible as they typically draw in very large volumes of air from outside, upsetting the air balance within the building. Combustion heaters can also be problematic for the same reason unless they have their own dedicated supply air duct.

Some products offer limited integrated heating or cooling via an MVHR duct system. These are known as post heaters or coolers, but are generally only able to provide sufficient whole house capacity for very high-performance buildings (e.g. certified Passive Houses). Typically outputs are in the order of 2 to 3 kW of heating and cooling.

Resources:

Passipedia, a knowledge portal developed by the International Passive House Association, includes information on controlled ventilation and blower door testing:

bit.ly/PP_CVent, bit.ly/PP_ATT

Passive House database of systems:

database.passivehouse.com/en/components

Renew article on MVHR: bit.ly/Renew_HRV2015

Sanctuary article on airtight design and when you might need MVHR: renew.org.au/sanctuary-magazine/energy-appliances/airtight-design

Further reading

Efficient homes

Efficient homes

Tradies and the transition

Do we need as many tradies for electrification as many think? Not if we are innovative, writes Alan Pears.

Read more Efficient homes

Efficient homes

Double glazing on the (very) cheap

Do we need as many tradies for electrification as many think? Not if we are innovative, writes Alan Pears.

Read more Efficient homes

Efficient homes

Ditching the shower fan

By fitting a lid on the shower, exhaust fans are not needed when showering. John Rogers describes this simple retrofit, using both a commercial product and a great looking DIY version.

Read more