Mottainai vs methane – The case for textile recycling

Sarah Coles explores the environmental and social benefits of diverting textiles from the waste stream, looks at industrial fabric recycling and takes inspiration from the Japanese practice of maintaining clothing for a lifetime.

In the 1965 film The Sound of Music, while the Captain is away in Vienna, Maria makes playclothes for the children out of old curtains. Perhaps taking this iconic filmic moment of upcycling as inspiration, my mother made a kaftan out of bright orange curtains in the 70s. “I was up there with the fashion,” she says. The orange kaftan was both fashionable and ethical, it seems.

According to the Australian Bureau of Statistics, Australians throw out approximately 570,000 tonnes of leather and textiles per year, only 12% of which is recycled. This means each year roughly 500,000 tonnes of leather and textiles end up in landfill in Australia. Once textiles are in landfill they decompose and release methane, a harmful greenhouse gas. Dyes and other chemicals may leach into the soil, potentially contaminating groundwater.

Modern day slavery was exposed in 2013. The collapse of the Rana Plaza in Bangladesh shows that modern supply chains are constantly chasing the cheapest workforce…we need to think more about why clothing is cheap and seek out ethical makers.

The ecological and social burden of new clothes is well documented. The introduction to the 2013 book Sustainability in Fashion and Textiles reads: “Considering the whole textile chain, from spinning to finishing…large amounts of water and energy are used and, in general, non-biodegradable wastes are produced.” According to the report ‘The State of the Apparel Sector 2015’, it requires 2720 litres of water to produce one new white cotton T-shirt. In the textile manufacturing sector, sweatshops and child labour are prolific, and working conditions abysmal. The fashion industry promotes continual consumption; according to a Food and Agriculture Organisation (FAO) report, worldwide demand for textile fibres was 69.7 million tonnes in 2010. In short, the textile industry is brutally unsustainable.

In a 2006 report by the European Science and Technology Observatory, ‘Environmental Impact of Products’, clothing accounts for between 2% and 10% of consumers’ environmental impacts. A great deal of what we throw away can be reused and recycled. Significant environmental savings are achieved by choosing recycled textiles over new clothing. A 2010 report by researchers at the Technical University of Denmark ‘Environmental benefits from reusing clothes’ looks at the life cycle impacts of clothes that are disposed of by incineration compared with that of clothes that are reused by charity groups. (Incineration is a common waste management practice in some countries, where space for landfill is at a premium.) According to the report, reuse of textiles saves 4 kg of CO2 for every kilogram of textiles saved. Although incineration is less common in Australia, textile waste in landfill still forms leachate and methane gas as it breaks down.

One method of diverting clothes from landfill is donating them to an op shop. Members of the National Association of Charitable Recycling Organisations (NACRO) operate thousands of op shops around Australia and are the largest and oldest recycling/reuse cohort in the country. Kerryn Caulfield, CEO of NACRO points out, “While charitable recyclers rescue secondhand clothing from landfill, their governing principle is one of benevolence; they accept donations to clothe those without and raise money for charitable purposes and to provide work for the disadvantaged.” She adds that the function of charitable recycling was “formed before federation—long before the term ‘landfill’—as a system to care for those in Australian communities who are in need.”

There are three sources of textile waste: pre-consumer, post-consumer and industrial. Pre-consumer waste is produced during the production of fibres and textiles; examples include off-cuts, selvages and shearings. While some of this is recycled (cotton off-cuts into cotton wipes for example), most is sent to landfill. Post-consumer waste is household waste such as sheets, towels and clothing. It is common for post-consumer waste to be recycled as secondhand items sold in op shops or exported to third-world countries. Industrial waste is generated from the manufacture of items such as carpet and curtains, and the end of life of things like conveyor belts and hospital sheets. This category is deemed ‘dirty waste’ and is sent to landfill.

Clothing that is too worn to sell in op shops can be recycled into such things as car insulation, roofing felts, rag rugs, loudspeaker cones, recycled fabrics, car polishing rags, cleaning cloths, mattress filler or furniture padding. The Smith Family’s commercial enterprise recycles textile industry waste and surplus clothing donated to the charity to produce things such as carpet underlay, furniture removal felt and weed suppression felt. Textile recyclers grade material according to type and colour. Textiles are shredded into ’shoddy’ fibres, which are then blended with other fibres for weaving or knitting.

Japan has many cultural traditions encouraging the avoidance of waste through the practice of using objects for their entire life cycle, by prolonging their use through repair. ‘Mottainai’ is a Japanese term conveying regret over wastefulness; the English version being ‘waste not, want not’. In 2002 the government of Japan released ‘The 2002 White Paper on the

Recycling Society’, urging citizens to end the vicious cycle of mass production, consumption and disposal.

In years past, it was normal for Japanese families to purchase new clothes for the first child, which were mended, patched and handed down to younger siblings, and eventually repurposed as cleaning rags. Kimono robes were handed down from mother to daughter. These days, demand for recycled clothing is on the rise in Japan as are ‘custom shops’ that specialise in vintage blue jeans. Custom shops allow customers to bring in clothes that they no longer wear to be refashioned, a practice known as ‘Mottainai fashion’.

Jane Milburn is no stranger to refashioned textiles. Jane founded Textile Beat, an enterprise that “taps into growing interest in ethical and sustainable ways to reduce our clothing footprint.” Jane has an agricultural science degree and her first job was as a rural reporter with the ABC. With Textile Beat her skills are all coming together; her childhood on a sheep farm in New Zealand, her love of natural fibres, her knowledge of agriculture and her experience working in communications. “I’m using all those skills to highlight the fact that we are overusing our resources. Only one-third of new clothing now is made of natural fibres, two-thirds use synthetic fibres that are mostly derived from petroleum.”

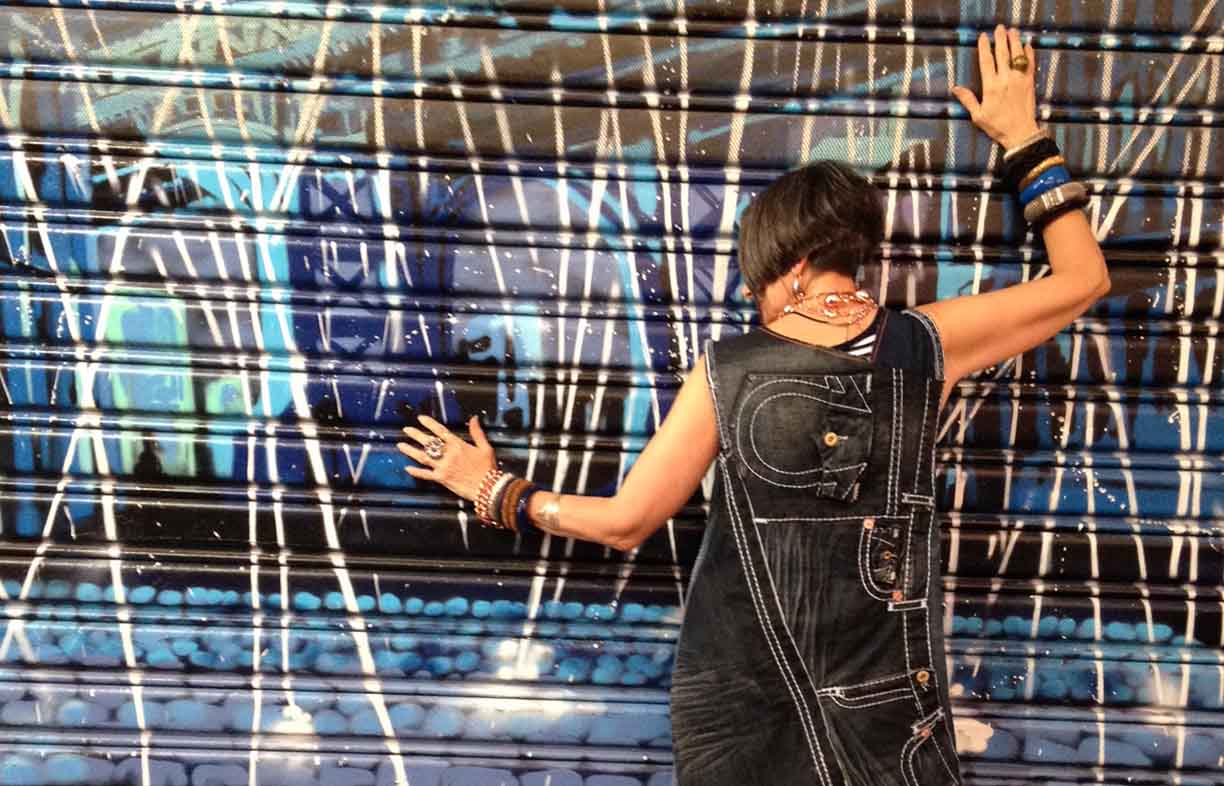

In 2014, Jane embarked on the Sew it Again Project, which she describes as “an upcycling project where I was rejigging things in my own wardrobe or that I found in the op shop.” Jane wrote 365 blog posts that year, most of them documenting her own creations and the work of other “adept recyclers”.

In 2016, Jane started The Slow Clothing Project, a project aiming to spark a conversation about clothing reuse. 130 people around Australia are “making something, and taking photos of the process, to showcase their ideas about clothing, making for themselves, and reusing existing textiles.” Jane says, “It is all about using natural fibres, handmaking and the story of the maker.” Forty garments will be generated across 40 weeks from February to November 2016. All of them will be documented through the Textile Beat website.

The textile trade is an ethical minefield. On a global average, individual consumption has gone from 7 kg per person of apparel fibre per year to 13 kg per person, according to the FAO. Jane says, “The sheer volume is a problem. That figure is what you’re adding to your wardrobe. Developing nations of course wouldn’t have anything near that, which means that in countries like ours it is probably a lot more than 13 kg.”

I feel that we need to have another look at what is going on because sewing is a life skill, just like home cooking.– Jane Milburn, Textile Beat founder

Research by Dr Mark Browne, an ecologist, documented in ‘Accumulation of Microplastic on Shorelines Worldwide: Sources and Sinks’, shows that synthetic fibres are shedding microplastics into the waste water stream with every wash, particularly the fleecy fabrics. Experiments sampling wastewater from household washing machines demonstrated that a single synthetic garment can produce more than 1900 fibres per wash. This suggests that a large proportion of microplastic fibres found in the marine ecosystem originate from washing machines.

Tips for recycling end-of-life clothing

Charities are not dumping grounds for unusable clothing. But some do collect poor-condition clothing that can be recycled into industrial rags, sound-absorbing materials, insulation and stuffing. You need to check if your local charity accepts ‘rags’ and label them accordingly. To be recycled clothing needs to be clean (no dirt, oil, grease, paint) and absorbent (t-shirts, towels, flannelette, sheets, but no denim). You can search for outlets in your local area at www.recyclingnearyou.com.au. Your local community garden, Landcare or Bushcare group may also be interested in some clothing, preferably natural fibres, which can be used for weed matting.

In 2013, an eight-storey building in Bangladesh housing textile factories collapsed killing over 1000 workers. Jane says, “Modern day slavery was exposed in 2013. The collapse of the Rana Plaza shows that modern supply chains are constantly chasing the cheapest workforce…we need to think more about why clothing is cheap and seek out ethical makers.”

Jane equates the burgeoning interest in the sensory aspects and integrity of the slow food movement with the growing interest in slow textiles. Jane is well-versed in the Japanese culture of recycled textiles. “There is a huge amount of potential in natural fibres. They are worth valuing and giving a second life. I feel that the more that you wear them, the softer and more beautiful they become. The Japanese culture really values that. They’ve got Boro stitching (see box), and they are continually reusing.”

Jane says that the lost art of sewing has huge potential. “At Woodford Folk Festival on the weekend I had several men come along to workshops who were darning their jeans.” She adds, “It is so empowering to be able to apply your own creativity and energy and to be able to say ‘I made it myself’. You can’t put a price on that.”

Boro and sashiko

Japan is famous for its silk kimonos, but as the practices of upcycling and zero waste gain traction, the style of clothing worn by peasants in pre-industrial Japan is experiencing a comeback. ‘Boro’, a term that describes mended and patched fabrics, was the clothing worn by peasants, merchants and artisans in Japan during the 19th and early 20th centuries. Boro describes clothes or household objects (such as bed covers) that are made from rags and patches of homespun hemp and cotton. The garments are repaired and maintained throughout the owner’s lifetime.

The rural population of pre-industrial Japan couldn’t afford new clothes and the thrifty techniques of Boro emerged. Japanese people repaired and recycled objects such as fishermen’s jackets and futon covers, handing them down from generation to generation. Boro fabric is almost always indigo in colour, because laws during the Edo period (1603–1868) restricted the working class from wearing bright clothes. Indigo is made from cotton dyed using the fibre of the indigo plant in the genus Indigofera (or in colder climates like Japan’s Ryukyu Islands, Strobilanthes cusia). In Japan, the fibre was fermented into a dye pigment called sukomo, then the fabric was added, before being dried in the sun. Indigo dyeing strengthens the fabric, one reason for its use in work clothes.

Sashiko, or ‘little stabs’, is a type of stitch developed in rural Japan, in a culture that prized mending over consumption. Made using a thick embroidery-like thread, sashiko stitches are visible and often follow a regular pattern. Originally a rough, free-form stitch, sashiko developed into an elaborate decorative style.