Sustainable building materials: the choices we make

Alasdair Taylor from Light House Architecture & Science unpacks the environmental impacts of building a home, and offers four ideas to make the process more sustainable.

Every choice we make has its impact on the global environment, from tiny soot particles rising from your candle to the enormous coal plants still sputtering out electricity. The largest choice most people make is the largest thing many of us own: our homes.

Consider the size of a building (let alone the cost!) and imagine the amount of work that went into it. The cutting of timber, the mining of gypsum, the wrapping rubber around the wires, the extrusion of aluminium window frames—each piece of the building has a story. All that work has an environmental burden, and it all adds up.

But what is an environmental burden when it comes to our homes, and what would we do about it anyway? We will grapple with these questions and more below. There is a lot of information, but I promise that you can make a difference with some straightforward actions, and hopefully get a better idea of what a sustainable building is in the process.

Embodied carbon

The word “embodied” in constructure broadly refers to the physical materials that go into a project. This is simple for most things: embodied timber would just mean the timber used within the house, but for some things, like embodied carbon, it can get more complex.

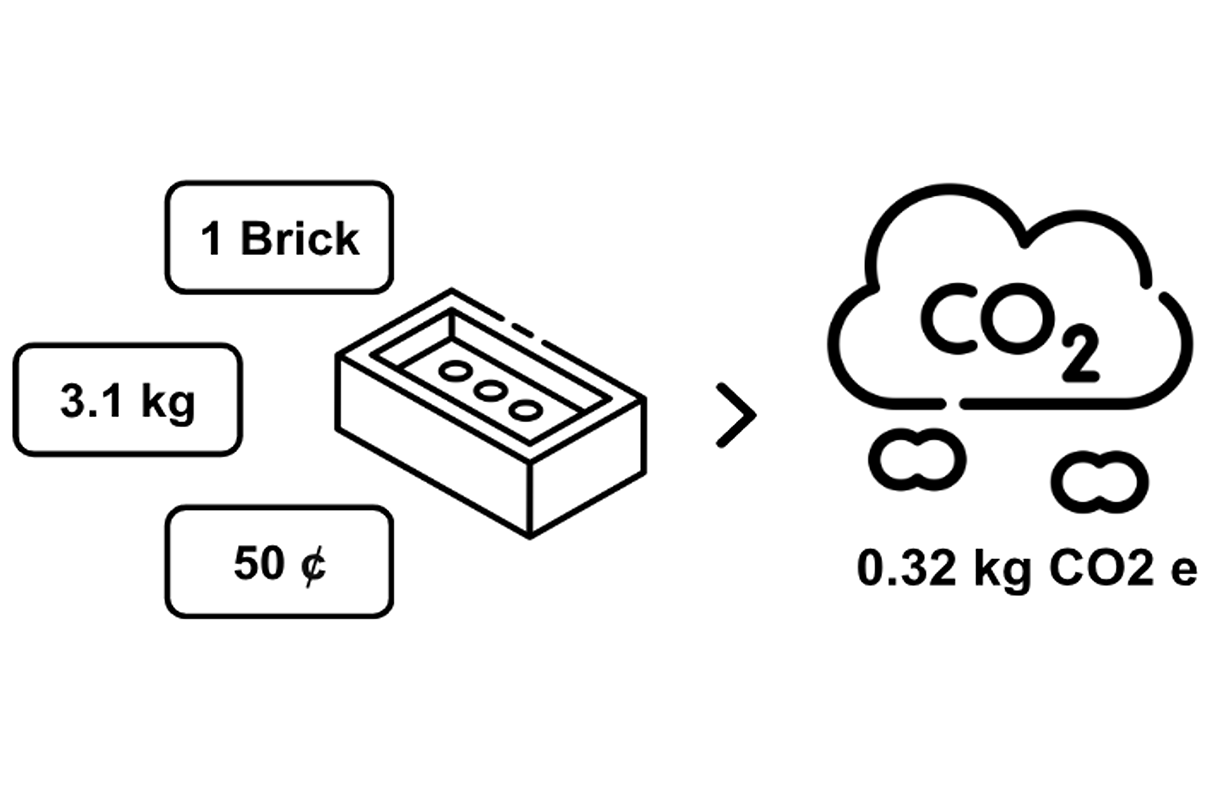

Embodied carbon refers to the total sum of carbon dioxide emissions in each and every part of a building. A single product—such as a brick—is responsible for a certain amount of greenhouse gases being emitted. We tally that in a few ways, depending on the material used.

For example, we can measure the emissions of a brick by its weight, by the number of them in a wall, by the area of wall used, or by the cost related to the brick. This can seem confusing, but it boils down to a number connecting the environmental burden to the building material used.

The most important environmental burden is global warming potential (GWP). This measures all greenhouse gases emitted and converts them into carbon dioxide. There are other environmental burdens that we have to consider, but none are as important as GWP.

A building has two kinds of emissions: embodied carbon and operational carbon dioxide emissions. Operational carbon looks at the impact of the operation of the building—including water, electricity and gas use.

Operational carbon is still the most important of the two in most buildings in Australia, but with solar panels, grid decarbonisation and better buildings, embodied carbon becomes a critical consideration.

We know now that embodied carbon is the environmental burden of the materials that make up the building. This burden comes from the production, transport, repair and disposal of these materials.

There is plenty of information, experience and industry support to help understand and limit operational carbon, but not much when it comes to the embodied aspect. It is now a legislated requirement for designers to limit operational energy use, which is linked to operational carbon, but only a few designers design with embodied carbon in mind. This is something we’re doing at Light House Architecture and Science.

My story so far

Jenny Edwards, director of Light House, has already spent much of her career speaking on practical building efficiency—championing thermal passive, small, draught-sealed and well-insulated homes.

Our practice pulls together considerate design and building science when it comes to air leakage testing, thermal imaging and thermal efficiency modelling. I began researching embodied carbon, building life cycle assessments (LCA) and anything else I could find about sustainability. I tried different tools, different approaches, attended far too many webinars, read the scientific papers, found the experts and asked the questions. I can speak on building sustainability as someone who has experienced all the confusion that comes with it.

At Light House, we’ve now changed our concrete slabs, pushed for specific timber selections, and begun the conversation about embodied carbon with our builders and clients. I’ve had the conversations with our architects balancing cost, practicality, time constraints, aesthetics, sourcing, etc. with sustainability and embodied carbon.

Your solutions can be as complex as you’d like, but some of the best improvements can happen without changing construction approaches or using experimental materials or costing the world.

Solutions

I’ve got four ideas that will help you understand and apply building sustainability principles. There is more to it than this, but these can still address some major issues without going too deep.

Firstly: renovate, retrofit, reuse, recycle, replace, repair, recreate and minimise. No material on the market is carbon neutral without offsets, so the solution to limiting a building’s embodied carbon is to limit the building itself.

Build small where you can and scrutinise what is needed. When possible, work with what you already have, whether that’s an existing building or space. The smaller a project, the smaller its embodied carbon.

Over 80% of Light House projects this year are additions or alterations. This type of building is more affordable, uses far less embodied carbon, and importantly, fulfils the same demand for new buildings without building them! A smart renovation can make a building unrecognisable, while stopping lots of materials from being tossed.

Secondly: use local materials. This is a simple idea; the further a material needs to travel to get to site, the worse the emission, but there is still some nuance here.

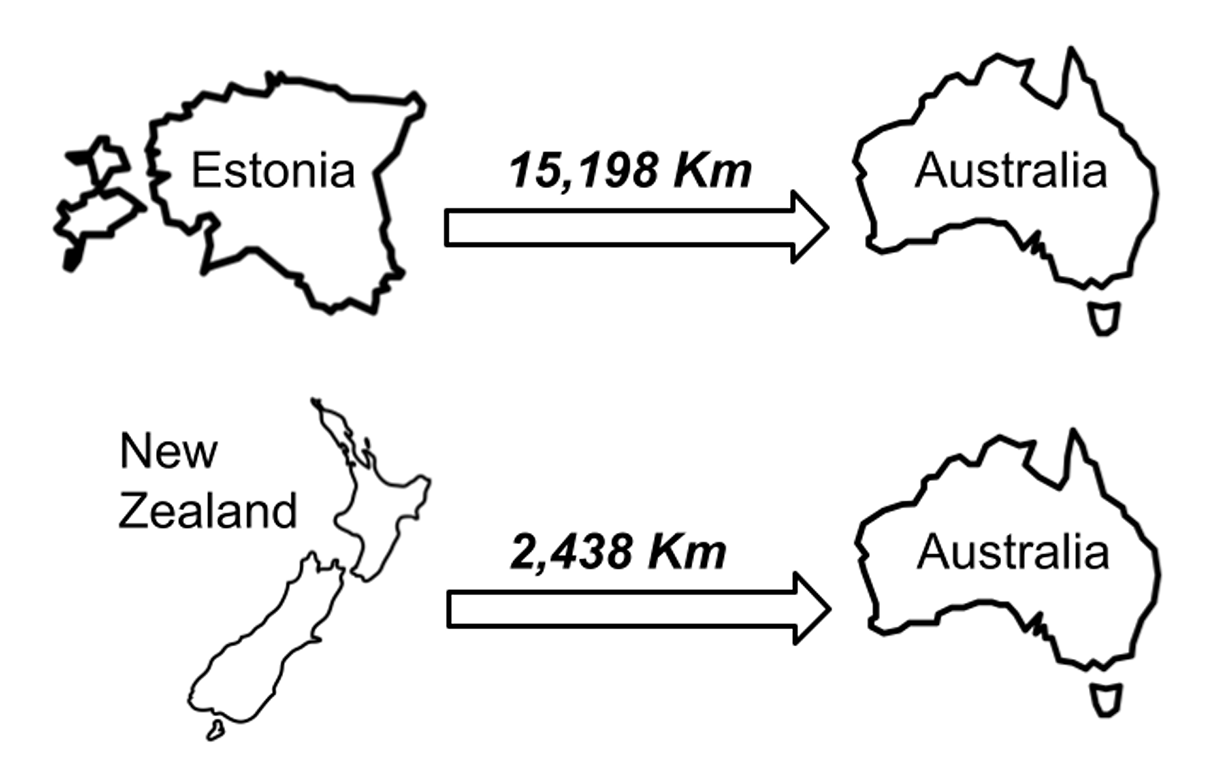

Overland diesel trucks are often worse for the environment than long distance shipping. Australia is a big place and ordering glulam for Queensland from Victoria means a lot of trucking. However, cargo shipping Cross Laminated Timber from Estonia when there are manufacturers in New Zealand is still a bad choice.

The answer is rampant localisation, and building with the right materials that are close at hand. Look at the distance from the manufacturer to the site, not from the supplier to the site. Trying to work out where even one part of your building is manufactured is a good exercise in sustainability. Anything that makes you stop and think about the materials you are using and where they come from is a victory.

Thirdly: be selective about high emissive materials. All materials can have a place in a building, and many sustainable homes use high emissive materials for one reason or another. These materials are generally mined products like steel, cement, gypsum, lime, aluminium, silicas (like glass and clay) and others, or products with high levels of manufacturing, such as fired bricks and aluminium window frames that are mined and processed before being extruded into shape.

Please note the important word choice above: be selective. How would you like to live in a house without copper wires? These materials are often the best choice for a specific purpose, but a bad choice for another. Copper sheeting on a covered external wall may look nice but is more emissive than a bio-based option.

Most new constructions in the ever-growing list of new suburbs in Canberra have concrete pillars, walls, and levels that could easily have been designed with lightweight framing. Considering the embodied impact of materials and assemblies at the concept stage of design costs nothing but can make all the difference in the environmental impact of the build.

Lastly, if you’re using wood, or wood products, get them from local plantations. To avoid those high emissive materials, we often turn to wood. This isn’t a bad idea at all; wood is great for lots of reasons but is certainly not a silver bullet.

Timber can have the worst environmental impacts of all. The simple position is to avoid the logging of native forests, old or regrowth, and focus on local plantations. Avoid intercontinental woods, as we should encourage existing local producers and should limit the distance from manufacturer to site. Forestry is a highly emotive topic and should be looked at carefully.

To summarise, renovate with local, low-emissive materials, and use plantation timber. Remember to build for energy efficiency, aesthetic beauty and functionality as well. An ugly building will be torn down at the first opportunity, but a good-looking, functional one can last as long as its materials, and sometimes longer still.

What now?

This article should have given you the foundation of sustainable building and some ideas about how to go about it. Have a look at some case studies from Light House and other great architects to see what sustainable homes can look like.

I’m sure you have questions, want more details and would like specific recommendations. I will be writing more articles, and going into detail about important materials, in future issues of Renew magazine. In the meantime, feel free to contact me directly. Good Luck!

Further reading

Climate change

Climate change

Charting possibilities of the blue economy

Mia-Francesca Jones explores the opportunities of the blue economy for oceanic health, as well as human and planetary wellbeing.

Read more Pears Report

Pears Report

Energy forecasts, hydrogen hype and questions of progress

Alan Pears gives us his round-up of the main energy issues this quarter.

Read more Pears Report

Pears Report

Energy costs, climate impacts and quality of life

Alan Pears brings us the latest news and analysis from the energy sector.

Read more