Comfortably ahead: A tale of two heaters

Turn on your air conditioner—and knock hundreds of dollars off your heating bill. Tim Forcey describes the learnings (and savings) gained from his experiment with reverse-cycle electric heating.

This article was first published in Issue 133 (October–December 2015) of Renew magazine.

Over the last 20 years my wife and I have raised a family in our 100-year-old Melbourne bayside weatherboard home. Last spring, following our third partial renovation, we installed two air conditioners in preparation for the hot summers to come—particularly so my wife and I could stay comfortable when working at home.

The two air conditioners we chose did just that, easily cooling our full ground-floor living space (128 m2 consisting of seven rooms and a hallway). Based on advice from Matthew Wright (founder of Pure Electric), we opted for two top-of-the-line Ururu Sararas (US7s) manufactured by Daikin: one small wall-mounted unit in our front bedroom (2.5 kW rated for cooling) and one medium unit (3.5 kW) in the lounge room.

The total US7 rated cooling capacity of 6 kW contrasts with a 14 kW multi-headed unit that the salesperson said we would need. So lesson number one: avoid the up-sell if your house is reasonably well-shaded and insulated (see below for more on sizing).

Come winter, I was keen to learn how these reverse-cycle units would compare with our 20-year-old ducted gas heater in terms of health, comfort, convenience and operating cost, particularly following on from research by Beyond Zero Emissions and Renew (formerly the ATA, Renew magazine’s publisher) into the potential for economic and environmental benefits from going off gas.

My findings? There were pluses and minuses when comparing the two heating methods on comfort and convenience. But when it comes to cost, the reverse-cycle air conditioners beat ducted gas hands down—not only for our home, but possibly for hundreds of thousands of homes around Australia.

Science — sort of — in the home

Starting in late June 2015 (mid-winter), I sought to heat our home on alternate days using the US7s and then ducted gas.

The US7s are heavily instrumented and can tell you the outdoor temperature, the indoor temperature, the indoor humidity and how much electrical energy they have consumed since you turned them on today, or since you installed them last year! Adding to this, I spread thermometers throughout our living areas. I also referred to our in-home electricity display that relays instantaneous electricity-use figures for our whole house from our smart electricity meter.

And for the first time in my life, often wearing a bathrobe and head torch, I journeyed out behind the bushes to the not-so-smart gas meter to diligently record gas usage.

I will not claim that this exercise was the best example of the scientific method we have seen. Variables and shortcomings had to be managed, such as failure to focus on the task-at-hand at 5.30 am before the morning coffee, Daikin’s less-than-fully-illuminating owner’s manual, and my co-occupants.

Ducted gas: reliable for years, but now at its use-by date

Our ducted gas system has served us reliably for 21 years. What Star rating our heater could have scored in the mid-1990s is unknown. Using figures taken from the owner’s manual plus further measurements and calculations, I learned the unit might be 75% efficient at getting 18.8 kW of gas-combustion heat into our under-floor ductwork. More efficient ducted gas heaters are on the market today such as those that use condensing technology.

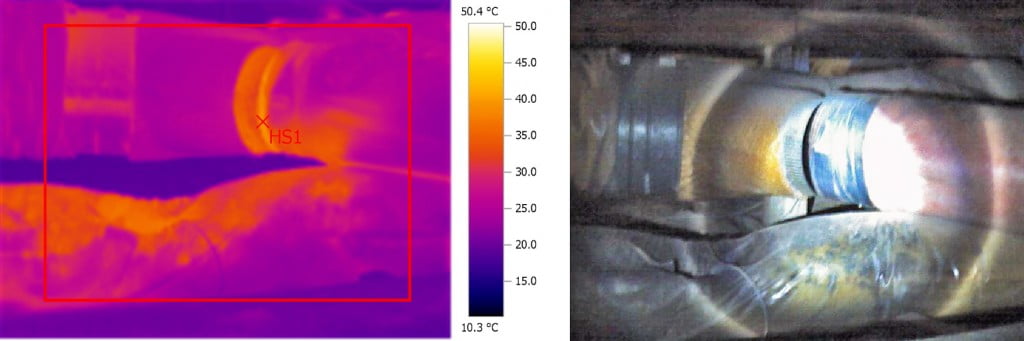

Getting heat into the ductwork and then getting it into the house are two different things. Unfortunately, I can’t readily inspect our underfloor ducting because of the tight crawl space, but our ducts are known to have been damaged by animals seeking a warm winter resting place. We managed to patch one hole when access was possible during a renovation. How well the ducts were insulated at day one and are now still insulated at day 7600 is probably summed up by the technical term “not that great”. Still, hot air does emanate from each of the eight registers, so that is a plus. I can say as a part-time home energy consultant that this isn’t true at every home!

Our ground-floor living spaces are quite zone-able thanks to renovation features such as cavity sliding doors. However, the ducted gas system is designed to heat all 128 m2 of our ground floor, whereas often my wife and I spend our waking at-home hours in the 52m2 represented by the kitchen, eating area and lounge room. Later in the evening, this is often reduced to the 18m2 of the lounge room.

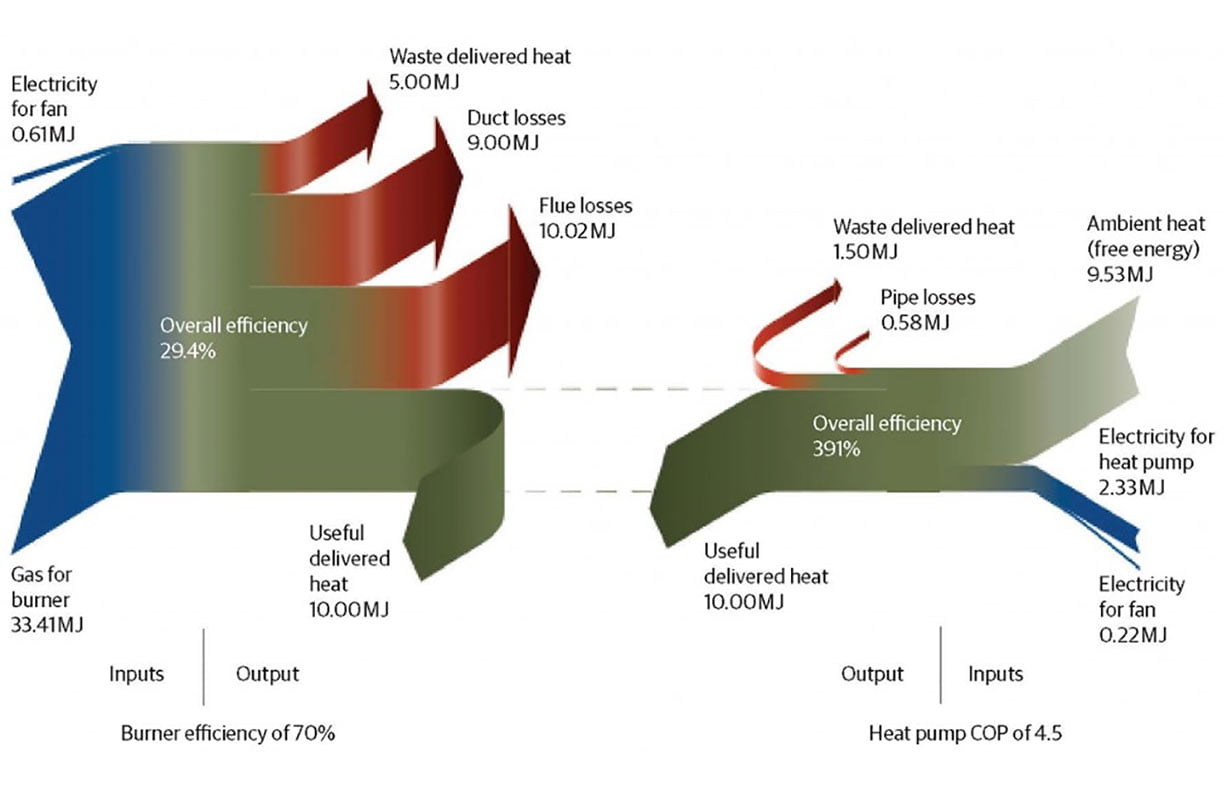

So there are losses and inefficiencies all along the way with ducted gas. Only some of the heat of gas combustion makes it into the ducts. Only some of that heat makes it into the house and only some of that makes it to the vicinity of our bodies. It might be optimistic to assume that we only throw away only half of the gas we buy for space heating.

Fortunately our last two renovations included an emphasis on insulation, draughtproofing, double-glazing and thermal window treatments. In mid-winter, most days we use heating for three hours, and never after bedtime (though our usage can extend out to nine hours on days my wife and I work from home). This means we pay only about $500 per year for the gas energy used for space heating.

Still, throwing away half of the gas we purchase seems like a waste. And it’s interesting to note that a ducted gas heating system also uses a significant amount of electricity, with our heater using a 300 watt blower to circulate air.

Thankfully, technology and changing economics mean that many Australians can now do better, especially if we happen to have a reverse-cycle air conditioner there on the wall, waiting to be used.

Goodbye gas, welcome to the era of electricity

You might think that Australia entered the era of electricity in the early 1900s. Well, we ain’t seen nothing yet! Conversion to an all-electric home and transport is not only being practised by enthusiasts but may well be the cheapest way to go for many of us.

One of Daikin’s contributions to this new electric era is the Ururu Sarara, or US7. The ‘7’ refers to the fact that the 2.5 kW model is 7 Star, currently the only 7 Star air conditioner on the Australian market. The words Ururu (‘wet’ in Japanese) and Sarara (‘dry’) refer to the way that the US7 employs not only a refrigerant cycle (as do all heat pumps), but possibly the first residential use of a desiccant wheel.

A desiccant wheel is a way to add or remove humidity (water) from the circulating air, at low energy cost and independently of the desired room temperature. This is an advantage in summer when we may want to lower air humidity without driving the living space to uncomfortably cold temperatures. In winter, the US7 is able to maintain higher humidity levels than ducted gas can achieve, resulting in health and comfort benefits.

COP that!

As shown at the Australian government appliance rating website, in heating mode the 2.5 kW US7 achieves a coefficient of performance (COP) of 5.8. This means that under test conditions, for every one unit of electricity used the device can deliver 5.8 units of heat. The extra 4.8 units of heat are collected as free energy from the air outside your home.

If a ducted gas system is only 50% efficient when it uses one energy unit of gas to deliver half a unit of heat, a 2.5 kW US7 is 580% efficient when it uses one energy unit of electricity to deliver 5.8 units of heat. So at this point in the comparison, the US7 leads ducted gas by a factor of 11.6 (580% vs 50%). Comparing the energy requirements of heat pumps versus ducted gas reminds me of the ‘now-a-no-brainer’ comparison we often make when considering halogen downlights and LEDs. Truly remarkable!

Note that the larger US7s have lower COPs: the 3.5 kW has a COP for heating of 5.05 and the 5 kW has a COP of 4.6—lower, but still much more efficient than gas. And, should you not own a US7, but rather a reverse-cycle air conditioner with a rating down toward3 Stars, don’t despair! Even a 3 Star unit achieves a COP of around 4 and may be eight times more efficient than ducted gas.

In fact, test-condition COPs may not fully express a heat pump’s capabilities. Test conditions specify an outside air temperature of 7°C, so any time the outside air temperature is greater than 7°C, a heat pump may perform better than its rating. Likewise, when the outside air temperature is less than 7°C, it may do worse. During my testing, the outside temperature rarely reached as low as 7°C when heating was required. Further, if at any time a heat pump is not required to operate at its full output, the heat exchangers in the unit will essentially be oversized and COPs higher than the rated figure can be achieved.

It is also worth noting that our wall-mounted US7s involve no air-transporting ductwork. Refrigerant moves between the indoor and outdoor parts of the heat pumps by short lengths of small-diameter and well-insulated piping, thus minimising energy losses.

Comparing the power

As listed on the US7 specification sheet, at full power our US7s can deliver about twice as much heat as their rated capacities, for a total of about 16.5 kW (heating). This means that our two US7s can deliver almost as much heat as our ducted gas heater, and possibly more heat than comes out of our gas ducts into our living spaces.

Because of their heating capacity, our US7s quickly warm the rooms in which they are installed. However, it takes more time if we are trying to also heat adjoining rooms.

The price of energy

Historically in Australia, if one wanted to buy one unit of energy (e.g. a kilowatt hour or kWh), gas was far cheaper than electricity. That is changing as eastern Australia has joined the ranks of regions that export gas to Asia. Our wholesale gas prices are rising towards international benchmarks. The cheapest block of gas on our bill costs 1.61 cents per megajoule (MJ) or the equivalent of 5.8 c/kWh (including GST).

On the electricity side, under the Victorian flexible pricing scheme, Powershop sells me (not-green) electricity at prices ranging from 25 c/kWh during defined peak times (3 pm to 11 pm weekdays), 10 c/kWh for off-peak (11 pm to 7 am), and 14 c/kWh for shoulder (all other times). (Note: These gas and electricity prices are for energy only and exclude fixed or network delivery charges, but include GST.) To sum up, the electrical energy we buy from Powershop remains more expensive than gas, but only by factors ranging from 1.8 (using off- peak electricity) to 4.3 (peak).

People exporting excess solar power to the grid may have to consider an even greater range of electricity prices before turning on an electric heater. These might range from ‘opportunity-lost-because-I’m-not-exporting’ costs of 66 c/kWh for those on the Victorian premium feed-in tariff, to only 5 c/kWh for a very un-premium tariff. If 5 c/kWh is all you are paid for selling electricity into the grid, that electricity has become less valuable than gas and is very ripe for you to use in gas-displacing ways.

As it happens, our house faces north and winter solar heat is trapped by double-glazed windows. Thus, we never have to activate our heating system when the sun is shining and therefore our heating demands don’t compete with our solar exports.

Combining the price disadvantage of electricity with the 11.6-times heat-pump efficiency advantage means that it is theoretically possible for me to use the smaller US7 at one-third to one-sixth the cost of ducted gas, depending on the time of day. For homeowners on the low solar feed-in tariffs, an efficient heat pump can possibly be operated at one-tenth the cost of gas.

Factors that might influence this equation are your geographical location and whether your system uses a crankcase heater; see box below. The US7 automatically turns off power to the outdoor unit when not in use, greatly reducing standby energy consumption.

The financial, comfort and convenience triple-bottom line

So with all my data recording, spreadsheeting, and generally making a nuisance of myself with fellow occupants, what did I discover?

The mid-winter ‘heat-up in the morning while getting ready to leave for work’ operation can be done with the US7s for around an average of $0.30 (including GST). This varies with different overnight weather conditions and whether off-peak or shoulder electricity tariffs apply. Using ducted gas to heat up the house costs more than four times as much at around an average of $1.30. Across a full day, heating with the US7 costs around an average of $1.50 whereas ducted gas costs $4.80. Heating with electricity during the peak tariff hours of 3 to 11 pm is more costly than at other times, but still beats ducted gas.

During the trials I was able to achieve a similar level of heating comfort with either method. Regarding convenience, with a flick of the thermostat, the powerful ducted gas system heats up quickly across multiple hot air outlet registers in every room. On the other hand, using the lounge room US7 to warm up the kitchen can be done, but requires a half- hour head start using the in-built timer.

The morning startup of ducted gas sends unwelcome hot dry air whistling into our bedroom where someone might be seeking those last few moments of sleep (“Shut-off the gas!”) So there are comfort and convenience trade-offs with either heating method.

I am still learning about all of the features available with the US7s whereas I have had 21 years to optimise the performance of our ducted gas. Features are now available from Daikin that use smartphone wifi/GPS gadgetry to activate your heater when you are travelling home and approach within, say, five kilometres of your house. (Possibly one can also find a way to do the same with a gas heater.)

Regarding humidity, comparing the US7 in heating mode versus in heating/humidity mode, we’ve found that the latter feels much nicer and warmer. This is something people have traditionally not liked about reverse-cycle heating (or any sort of heating for that matter) and Daikin has addressed this shortcoming.

The future is electrified

In the future, we will be heating predominantly with electricity and knocking hundreds of dollars off our annual gas bill. Heat pump hot water is next, so the energy portion of our gas bill will become quite small. Unfortunately the fixed gas connection charge will remain until the day our home is completely gas-free.

More info

The size of air conditioner you need will depend on your house design, layout and construction. If you have a house with good sealing, shading and insulation, you may find that you can choose a unit smaller than that suggested by installers, although their sizing tools may take insulation into account; for example, see the sizing calculator at Fair Air. Some experts suggest the standard sizing approach used by installers is based on lower/higher temperatures than needed, while others suggest that larger units may have advantages in faster startup times. If using a unit to cool more than one room, you may need to experiment. Tim Forcey recently found that his US7 was shutting down if they weren’t in the room housing the system as it had a motion sensor, but he was able to fix that by increasing the timeout to three hours.

There is a slow but steady move towards more eco-friendly refrigerants, ones with lower global warming potential (GWP). The Daikin US7 uses a hydrofluorocarbon (HFC) known as R32, with a GWP of 675. Compare that to the common older refrigerant R12, which was both ozone destroying and had a GWP of 10,900! Another common synthetic refrigerant, R410a (a mixture of R32 and R125) has a GWP of over 1700, so of the synthetics commonly used for domestic systems, R32 is a reasonable option.

The most efficient refrigerants theoretically are the natural refrigerants, including CO2 and hydrocarbon mixes, and these also have much lower GWPs; for example, CO2 has a GWP of 1. However, we are yet to see any domestic air conditioners that use CO2 and the few that use hydrocarbons have efficiencies no better than HFC refrigerant models.

While you might think that the change to less destructive refrigerants might have a detrimental effect on heat pump efficiency, the opposite has in fact been the case. That’s not because modern refrigerants are particularly more efficient, but rather because the type of refrigerant has less effect on efficiency than other aspects of system design.

For example, the move to variable-speed compressor motors, driven by computer- controlled inverter drives, has greatly improved the efficiency of the average heat pump. Indeed, electronic control of heat pump refrigeration systems is the single biggest efficiency improvement implemented in recent years. The use of electronic controls has also allowed for the use of electronic expansion valves, which can increase system efficiency several percent; they have a wider adjustment range than mechanical valves, so can operate over the wider range required by variable-speed compressors.

Electronic controls have also made heat pumps smarter, allowing them to throttle back when the unit has sensed that there is no one in the room, thus reducing energy consumption, ramping back up when people are again detected.

The design of the heat exchangers (called the evaporator and condenser) is also very important to heat pump system efficiency. The heat exchange surface areas and the resulting temperature differential between the refrigerant and the airflow directly affects the refrigerant operating pressures and hence the work required of the compressor in order to provide the required heating or cooling effect. The larger the heat exchanger, the lower the temperature differential and the greater the system efficiency.

Other factors that affect heat pump efficiency include the temperature differential between the heat source (outside air) and heat sink (inside air), as well as the suitability of the system and its refrigerant for the environmental conditions. Heat pumps required to work in very cold environments must be designed to operate in such conditions. If you live in Tasmania, for example, you would not buy a heat pump that can’t operate below an outdoor temperature of 0 °C.

The crankcase heater is a small heating element that can draw up to 50 watts. It is used to keep the refrigerant from condensing into a liquid in the compressor and mixing with the crankcase oil, making it ‘watery’ and an ineffective lubricant.

The heater runs all the time when the unit is off, unless the ambient temperature exceeds a particular setpoint. In warmer climates, the heater may not run most of the time, but in colder climates it may run even during the warmer months. In the worst cases it may add more thatn 1kWh of daily energy consumption to your air conditioner’s energy use–something that should be factored in when comparing costs.

When buying an air conditioner, it is worth finding out whether the proposed unit uses a crankcase heater and, if so, how often it is likely to run–you may have to contact the manufacturer for this information.

If your unit does use a crankcase heater then you can shut off power to the unit when not in use, provided that you turn the power back on at least 24 hours before you start the unit, to give the heater time to do its job and separate the refrigerant from the crankcase oil. Failure to allow adequate time for the heater to work results in damaged compressor bearings, resulting in reduced compressor life or even a burned out compressor.

This article was first published in issue 133 (October–December 2015) of Renew magazine. Issue 133 has ‘reuse & recycle’ as its focus.

Efficient homes

Efficient homes

Building for a changing climate

Are we building homes for the future, or for the past? Rob McLeod investigates how climate change is impacting home energy ratings and the way we build our homes.

Read more Reuse & recycling

Reuse & recycling

Recycled hydronic heat

Renew’s sustainability researcher Rachel Goldlust gives us a view of and from the Salvage Yard.

Read more Efficient homes

Efficient homes

Getting off gas FAQs

Do heat pumps work well in Australian conditions? Rachel Goldlust explains.

Read more