Energy efficiency front and centre: A renovation case study

Rather than starting again, this Melbourne couple opted for a comprehensive renovation of their well laid out but inefficient home, achieving huge energy savings and much improved comfort.

Julie and Jim’s house in the Melbourne suburb of Canterbury was ahead of its time when it was built in 1977, with large north-facing windows for natural heating, green glimpses at every chance to connect the occupants with the garden, and a bare-bones minimalist design “to the point of no decoration,” says Julie. “The house was designed to be part of the landscape,” she goes on. “It’s extremely modest and almost invisible from the street.”

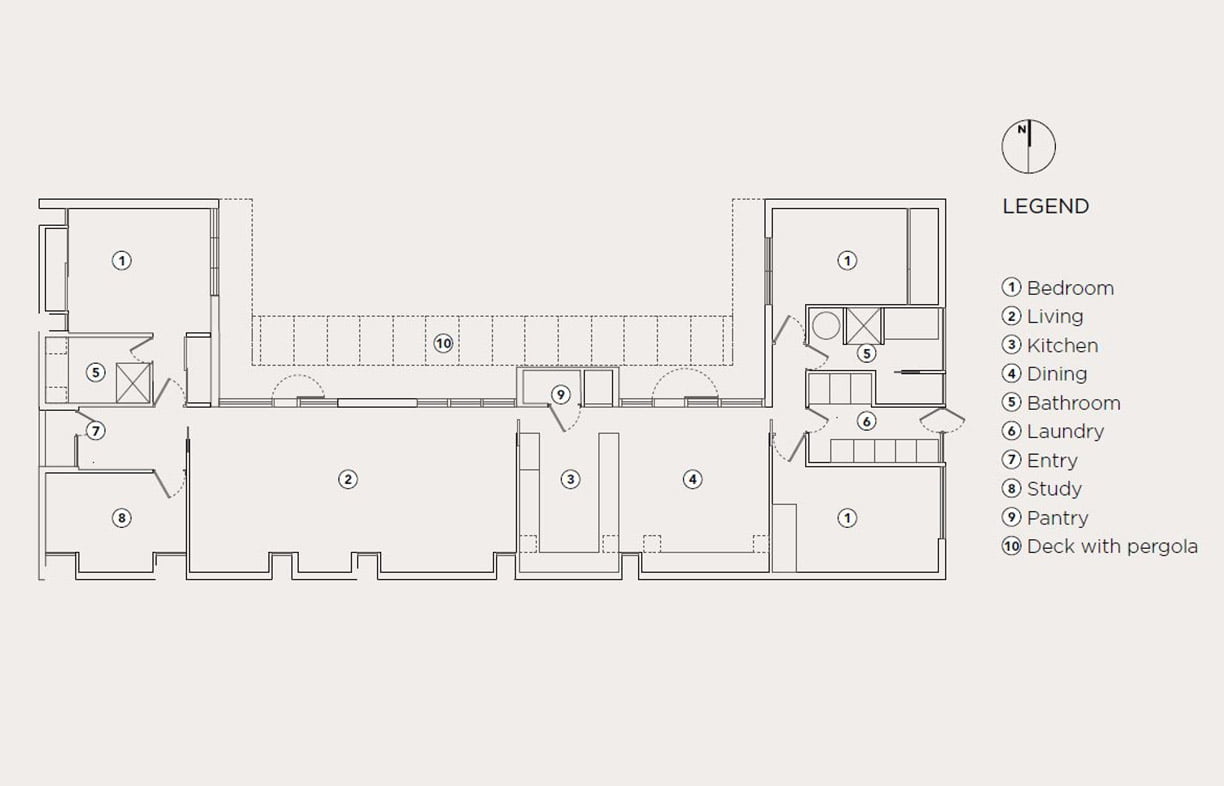

The house is an adaptation of a 1965 project home – the ‘Courtyard’ – designed by architect Graeme Gunn and built by Merchant Builders, who constructed over 2,000 architect-designed project homes in the 1960s and 1970s. “Their floor plans were excellent, almost radical,” says Julie. Their own C-shaped plan is one room deep, allowing excellent cross ventilation, natural lighting and connection with the private outdoor spaces. The design was clearly meant to be energy efficient with natural heating and cooling, however the house remained cold due to overly generous single glazing, too much uncovered thermal mass and air gaps throughout the home. “The construction wouldn’t pass muster today, and there was no insulation to speak of in the original ceiling,” says Julie. “The temperature was always around 10 degrees cooler inside than outside, and we wore beanies and down jackets in winter.” Expensive gas heating was needed to keep the house warm.

Due to extensive maintenance issues as a result of the poor durability of the external Oregon timber and undersized valley and box gutters, the couple very nearly knocked it all down to build a new architect-designed prefabricated Passive House, but stopped short, knowing how good the house could be with the application of modern-day building methods and materials.

They stepped way beyond just a retrofit or renovation to largely rebuild the house, keeping the original floor plan. The structure was stripped back and the bricks, floor slab, timber frame, beams, rafters and one bathroom retained. The couple say they took a holistic approach to energy efficiency on the project, opting to rebuild the roof to increase the space for insulation and using Passive House construction techniques where airtightness is the ultimate goal. The full-height windows were all replaced with custom-made double-glazed units, and insulation was blown into the walls while the roof was off.

The roof includes two vapour-permeable membranes for airtightness and a single service cavity within the insulated envelope. This houses all electrical, plumbing and air conditioning ducts to reduce the number of penetrations, and inevitably air gaps, throughout the home. The ceiling was restored to its original, unpenetrated state for greater thermal efficiency, rebuilt without the downlights a previous owner had installed over twenty years ago. Jim and Julie looked to the home’s original lighting instead, reinstating the pelmet lighting system that had been removed during an earlier renovation and adding a combination of LED spotlights and pendants. The skylights were moved and replaced with high-performing systems; in the process their surface area was reduced by around 70 per cent, again helping to minimise gaps in the thermal envelope. An airlock to the front door prevents further air losses.

The couple took the opportunity to make the windows smaller on the east and west to reduce heat gain in summer and minimise the cost of the custom-made double-glazed units. Meanwhile, original passive solar design features such as the one-metre eaves and pergola on the north still provide year-round benefit, admitting and restricting the sun throughout the year. Some of the previously uncovered concrete slab is now carpeted to better match the amount of thermal mass to window area.

The restoration and upgrade was completed in just three and a half months in 2020, and the results are impressive. The original passive solar design features are more effective now that the thermal efficiency is at a standard typically seen in today’s high-performing homes. All-electric systems such as a heat pump for hot water, reverse-cycle ducted air conditioning and induction cooktop replace gas appliances, and much of the home’s electricity is generated by a solar PV system over four times larger than the original system installed 16 years ago. “We’re using 75 per cent less energy than before,” says Julie.

“We’ve rebuilt the house to achieve the original design goal to be a quiet and energy-efficient residence. It’s so comfortable to live in now and the acoustics are better now too. It’s so much quieter than living in the old home, which is perfect because these houses are all about how they feel to live in.”

Further reading

House profiles

House profiles

Sparking joy

Clever spatial planning, high levels of insulation and a switch to all-electric make this stately Melbourne period home more liveable and efficient.

Read more House profiles

House profiles

Shadows and light

A Brisbane architect brings all his creativity to bear on the salvage and reimagining of a humble workers cottage into his own airy green oasis.

Read more